High-Performance Electric Fuel Pump Kits: Inline & In-Tank Solutions

🎁 A Personal Gift For My Readers

To support your project, I've secured an exclusive 8% OFF for you.

Simply paste the code at checkout.

💡 Use the savings to grab your extra fittings, oil lines, or connectors for free!

For modern performance builds and vintage EFI conversions, selecting the right electric fuel pump kit is the single most critical decision for engine safety. Unlike mechanical pumps that rely on engine RPM, an electric fuel pump kit uses electrical energy to drive a high-speed turbine or roller cell, delivering a constant, high-pressure fuel flow from the tank to the injectors.

Whether you are seeking an inline fuel pump kit for ease of access or an in-tank solution for maximum cooling, understanding the engineering behind these systems is essential for a reliable build.

What is an Electric Fuel Pump Kit?

An electric fuel pump kit utilizes electrical energy to drive a pump mechanism that continuously delivers fuel from the tank to the engine at a stable pressure. Compared to traditional mechanical pumps, an electric fuel pump kit provides higher flow rates (LPH) and consistent PSI, meeting the demands of high-horsepower modern engines and gas fuel systems.

Inline vs. In-Tank: Choosing Your Electric Fuel Pump Kit

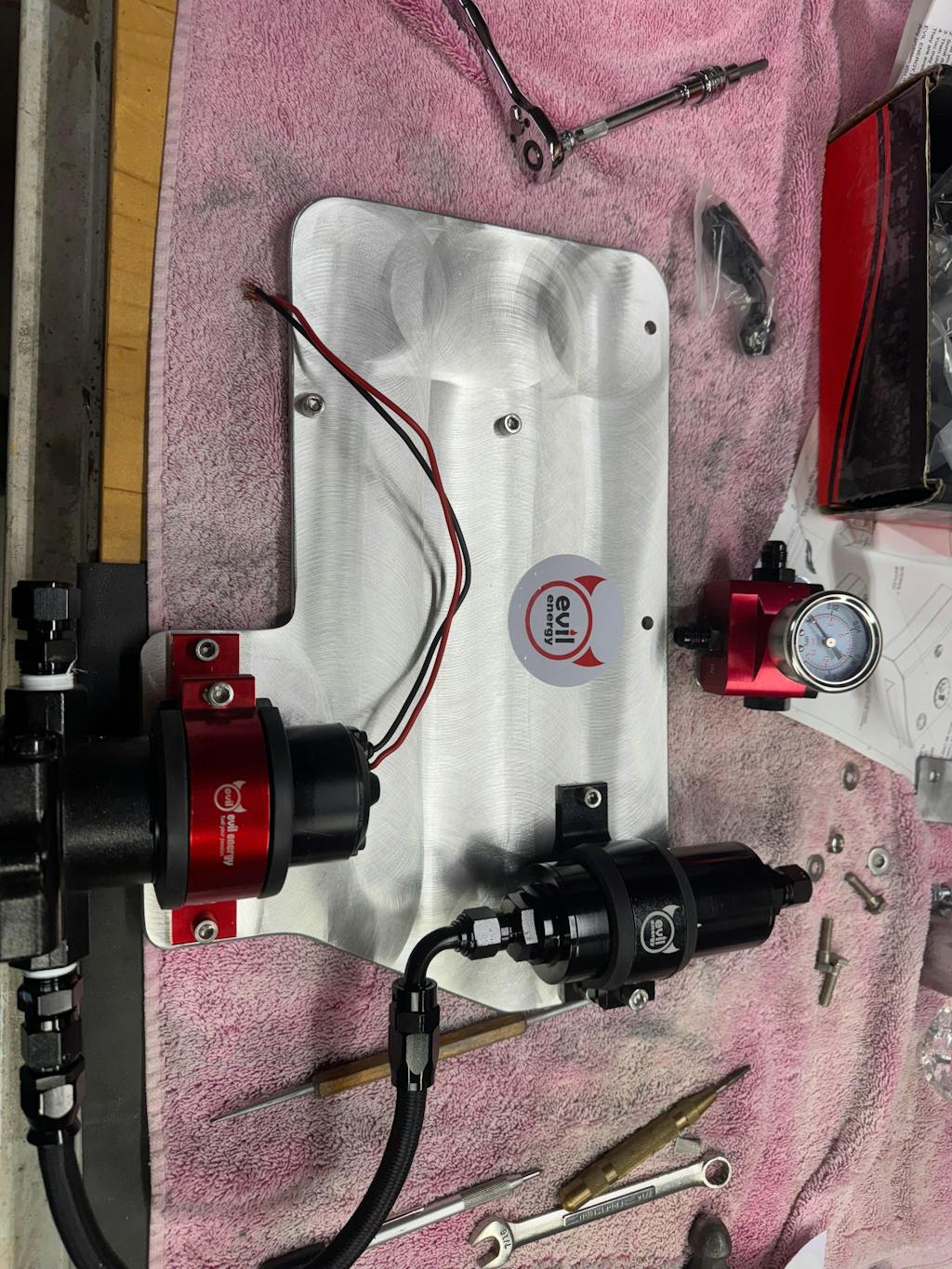

When browsing for an electric fuel pump kit, performance enthusiasts often debate the 'External vs. Internal' mounting strategy. Each has specific benefits depending on your chassis and performance goals.

-

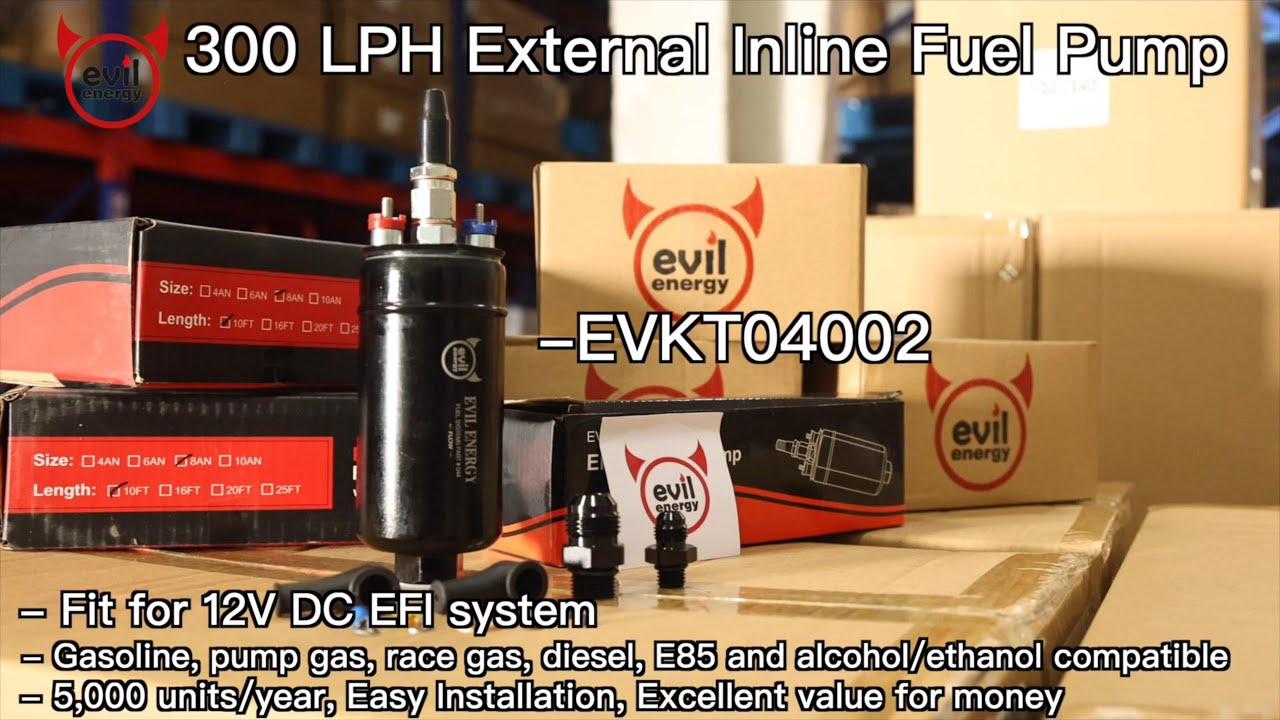

The Inline Fuel Pump Kit (External)

An inline fuel pump kit is mounted outside the tank, typically along the frame rail. This is a favorite in the racing community for its:

-

Serviceability: Easy to swap or inspect without dropping the fuel tank.

-

Versatility: Ideal for custom builds where the stock tank cannot house a high-flow pump.

-

Pro Tip: Always mount an inline fuel pump kit lower than the lowest point of the tank to ensure a gravity-fed supply, as external pumps are better at 'pushing' than 'pulling' fuel.

-

The In-Tank Fuel Pump Kit (Internal)

Most modern complete EFI fuel system kits utilize in-tank pumps.

-

Superior Cooling: The fuel acts as a heat sink, keeping the pump motor cool during long drives.

-

Noise Reduction: The surrounding fuel and tank structure dampen the high-pitched whine common in high-flow pumps.

The Journey: How Fuel Travels to Your Engine

Visualizing the fuel delivery path is crucial for troubleshooting. The fuel's journey begins at the electric fuel pump kit, but its path varies significantly depending on your plumbing choice.

-

Pickup: The pump draws fuel through a pre-filter sock.

-

Pressurization: The electric fuel pump kit generates the required PSI.

-

Filtration: Fuel passes through an inline high-micron filter.

-

Delivery: Fuel reaches the fuel rail via high-pressure lines.

-

Regulation: Excess fuel is either returned to the tank or managed via a regulator.

To master this layout, we recommend studying our Visual Guide to Fuel System & Tank Anatomy. Understanding this 'journey' is vital when choosing between Return vs. Returnless Fuel Systems.

Engineering for Performance: LPH and PSI

When purchasing an electric fuel pump kit, you must match the Liters Per Hour (LPH) to your target horsepower.

-

Naturally Aspirated: A standard 255 LPH electric fuel pump kit supports up to 500 HP.

-

Forced Induction: Boosted builds often require a 340 LPH or 450 LPH inline fuel pump kit to overcome manifold pressure.

-

Flex Fuel: If you are using our E85 Flex Fuel Guide to unlock 100+ octane power, ensure your electric fuel pump kit is E85-compatible to prevent internal corrosion.

|

Feature

|

Inline Fuel Pump Kit

|

In-Tank Fuel Pump Kit

|

|

Installation

|

Easier (Frame Mount)

|

Complex (Tank Drop)

|

|

Cooling

|

Air Cooled

|

Fuel Cooled (Best)

|

|

Noise Level

|

Audible Whine

|

Quiet

|

|

Maintenance

|

High Accessibility

|

Low Accessibility

|

Expert Troubleshooting: Forum Insights

Discussion on performance forums often highlights two main failures: Cavitation and Voltage Drop.

-

Preventing Cavitation: Often seen with an inline fuel pump kit, cavitation occurs when the pump is mounted too high or the feed line is too small. This causes the fuel to 'boil' and results in a loud whining noise and lean conditions.

-

Wiring Matters: A high-flow electric fuel pump kit draws significant amperage. Using factory thin-gauge wiring can cause a voltage drop, reducing pump output. Always use a dedicated relay and 10-12 gauge wire for your inline fuel pump kit.

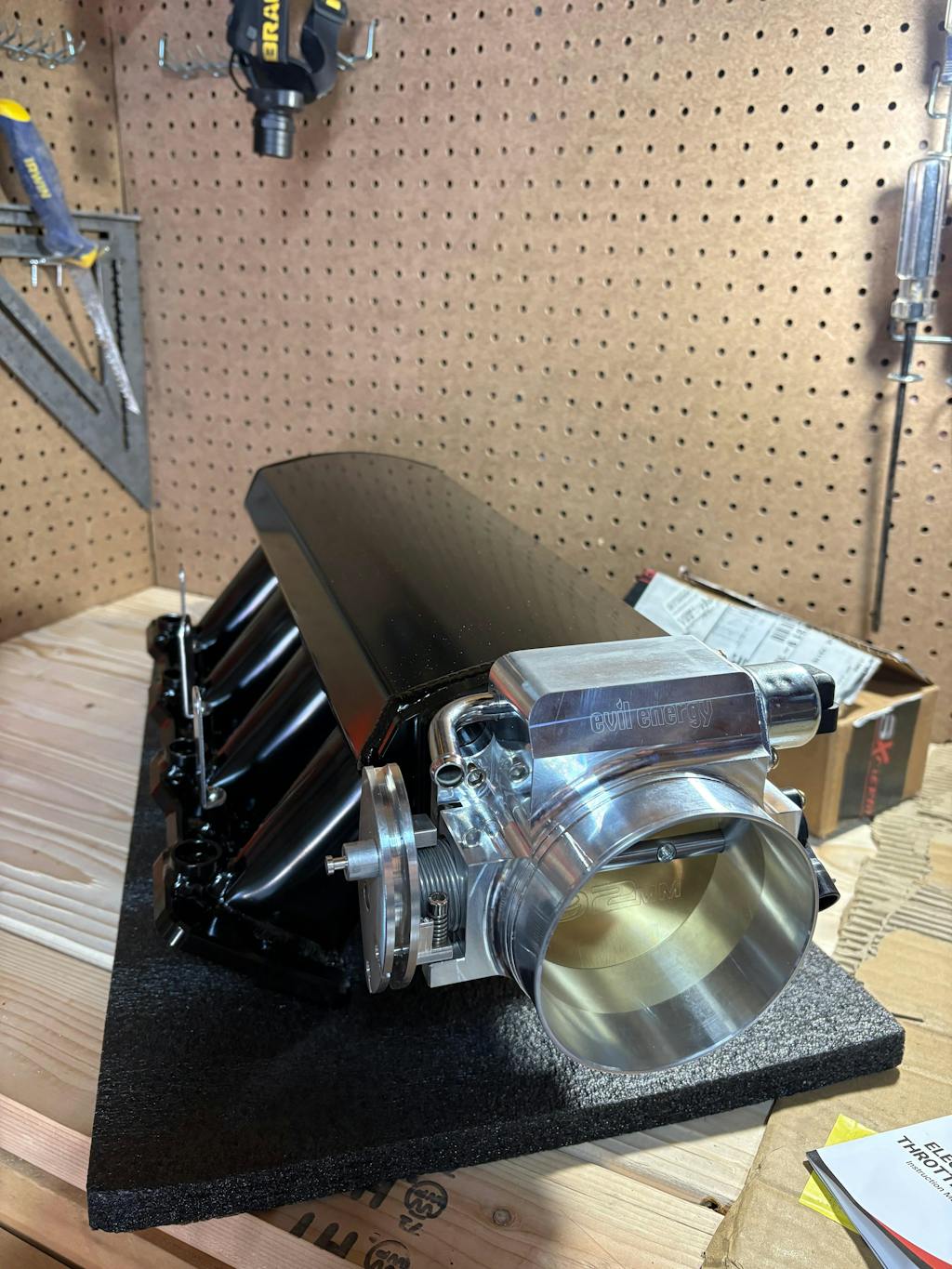

Why Choose EVIL ENERGY for Your Fuel Delivery?

Hardware quality dictates vehicle reliability. EVIL ENERGY's electric fuel pump kit solutions focus on three core engineering pillars:

-

PTFE Compatibility: Our kits are designed for modern E10/E85 fuels. PTFE lining prevents the chemical degradation and 'fuel smell' common with rubber lines, making it perfect for those following our E85 Flex Fuel Guide.

-

LS Swap Ready: We provide 6061-T6 aluminum AN fittings and quick-connect adapters to ensure a leak-proof seal at the 58 PSI standard required for LS engines.

-

Dual-Stage Filtration: Each inline fuel pump kit features a 100-micron pre-filter to protect the pump and a 10-micron post-filter to safeguard expensive injectors.

Conclusion: Power Starts at the Pump

Upgrading to a high-quality electric fuel pump kit is the foundation of any reliable performance engine. By choosing between a high-access inline fuel pump kit or a cool-running in-tank setup, you ensure your engine never runs lean under load.

FAQs: Mastering Your High-Performance Fuel System

Q1: Can I use an inline fuel pump kit with my factory fuel tank?

A: Yes, an inline fuel pump kit is a popular choice for EFI conversions on older vehicles. However, ensure the pump is mounted below the tank's fuel level, as external pumps are designed to push fuel rather than pull it.

Q2: What is the ideal PSI for an LS engine swap?

A: Most LS-based engines require a constant 58 PSI (4 bar). Using an electric fuel pump kit with an adjustable regulator is the best way to ensure your LS engine swap runs smoothly without leaning out.

Q3: Why is my inline fuel pump kit making a loud whining noise?

A: Excessive noise usually indicates cavitation. This happens if the pump is mounted too high, the inlet hose is restricted, or the fuel is overheating. Ensuring a gravity-fed supply to your inline fuel pump kit can solve this.

Q4: Is an electric fuel pump kit compatible with E85?

A: Not all are. If you plan to use E85, you must choose an electric fuel pump kit with corrosion-resistant internals and PTFE-lined hoses to prevent the alcohol from eating through standard rubber components.

Q5: Do I need a relay for my new electric fuel pump kit?

A: Absolutely. High-flow pumps draw significant amperage. Connecting an electric fuel pump kit directly to your factory wiring can cause a voltage drop, reducing pump performance and potentially melting wires.

Q6: What is the difference between a return and a returnless EFI fuel system kit?

A: A return system uses a regulator to send excess fuel back to the tank, keeping the fuel rail cool. A returnless system is simpler but can lead to vapor lock in high-heat performance builds. Learn more in the Return vs. Returnless Guide.

Q7: How often should I change the filters in my inline fuel pump kit?

A: We recommend inspecting the 100-micron pre-filter every 12 months and replacing the 10-micron post-filter every 10,000 to 15,000 miles to protect your injectors from microscopic debris.

Q8: Can a high-flow electric fuel pump kit overwhelm my stock regulator?

A: Yes. If your electric fuel pump kit flows more than the regulator can bypass, you will experience 'pressure creep.' In this case, upgrading to a high-flow bypass regulator is necessary.

Q9: Where is the best place to mount an inline fuel pump kit?

A: Mount it on the inner frame rail, as close to the fuel tank as possible. This protects the inline fuel pump kit from road debris while keeping it away from hot exhaust components that cause fuel boiling.

Q10: Why does my fuel pressure drop when I turn off the engine?

A: A slight drop is normal, but if it hits zero immediately, your electric fuel pump kit check valve or your regulator diaphragm may be failing, which can cause 'hard start' issues.

![[CPE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Fuel-Cell-Tank-Kit-Efficient-Fuel-System-Solutions-5-10-15-Gallon-EVIL-ENERGY-141125247_165x.jpg?v=1766341579)

![[PTFE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Fuel-Cell-Tank-Kit-Efficient-Fuel-System-Solutions-5-10-15-Gallon-EVIL-ENERGY-141125321_165x.jpg?v=1766341592)

![[PTFE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-LS-Swap-Fuel-Kit-_-Fuel-Filter_6AN-20FT-Fuel-Hose-_20-120PSI-Regulator-_-300LPH-High-Flow-Fuel-Pump-For-LS-Swap-EFI-Systems-and-More-_Copy_-EVIL-ENERGY-139826361_165x.jpg?v=1767074132)

![[CPE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-LS-Swap-Fuel-Kit-_-Fuel-Filter_6AN-20FT-Fuel-Hose-_20-120PSI-Regulator-_-300LPH-High-Flow-Fuel-Pump-For-LS-Swap-EFI-Systems-and-More-_Copy_-EVIL-ENERGY-139826246_165x.jpg?v=1767074132)