-

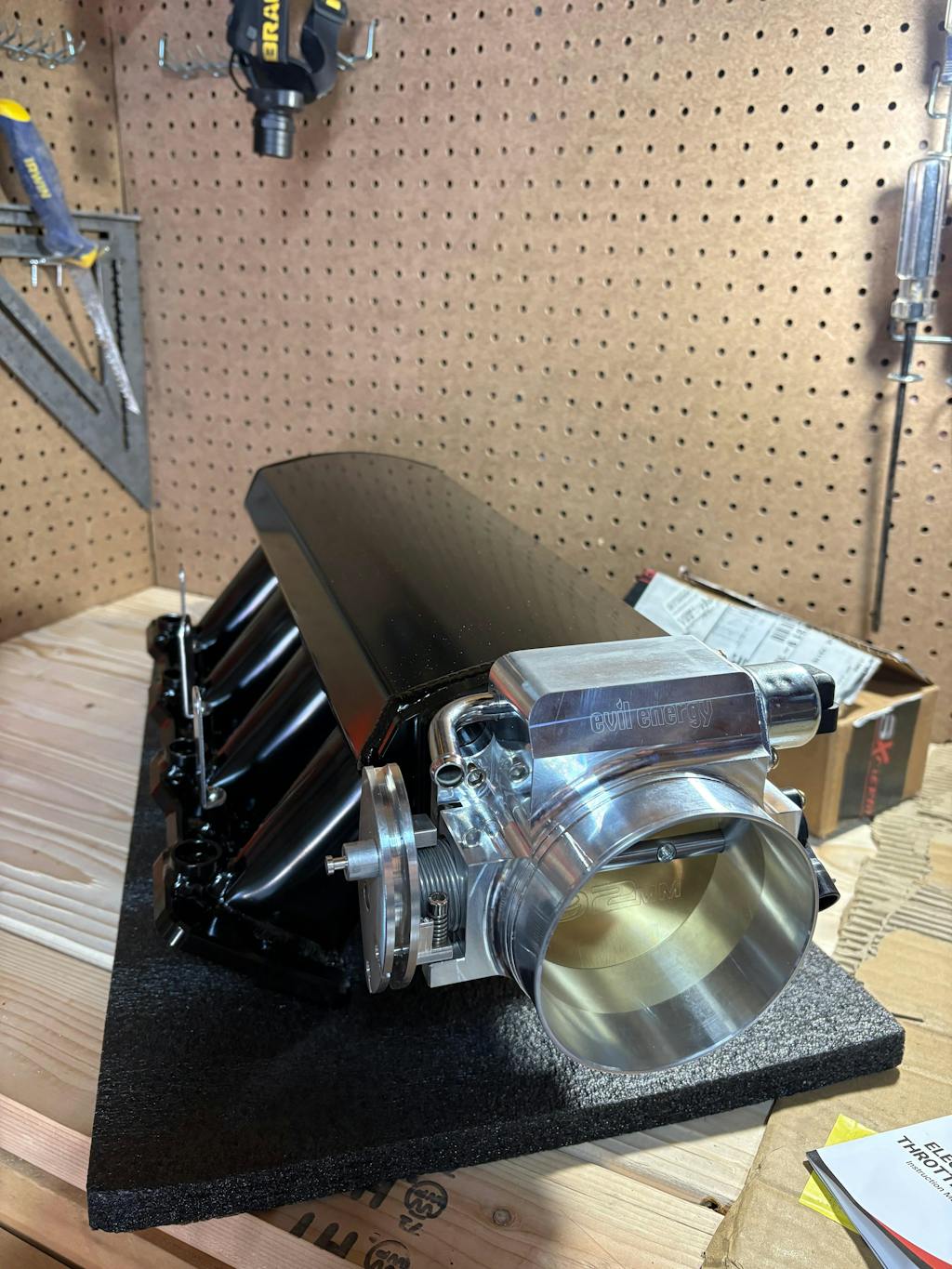

Evil Energy Intake Manifold + Fuel Rail Kit Bundle 300-137 For Single Plane EFI - GM LS1/LS2/LS6

- $139.99

- $139.99

$189.99- Unit price

- per

-

EVIL ENERGY Single Plane Mid-Rise EFI Intake Manifold for GM LS3 L92 V8 6.2L With Fuel Rail Kits

- $109.99

- $109.99

$189.99- Unit price

- per

-

Super Victor EFI Intake Manifold with Fuel Rail Kits for Gen III LS1, LS2 – High-Performance, Forced Induction Ready | 28095S | Evil Energy

- $139.99

- $139.99

$189.99- Unit price

- per

-

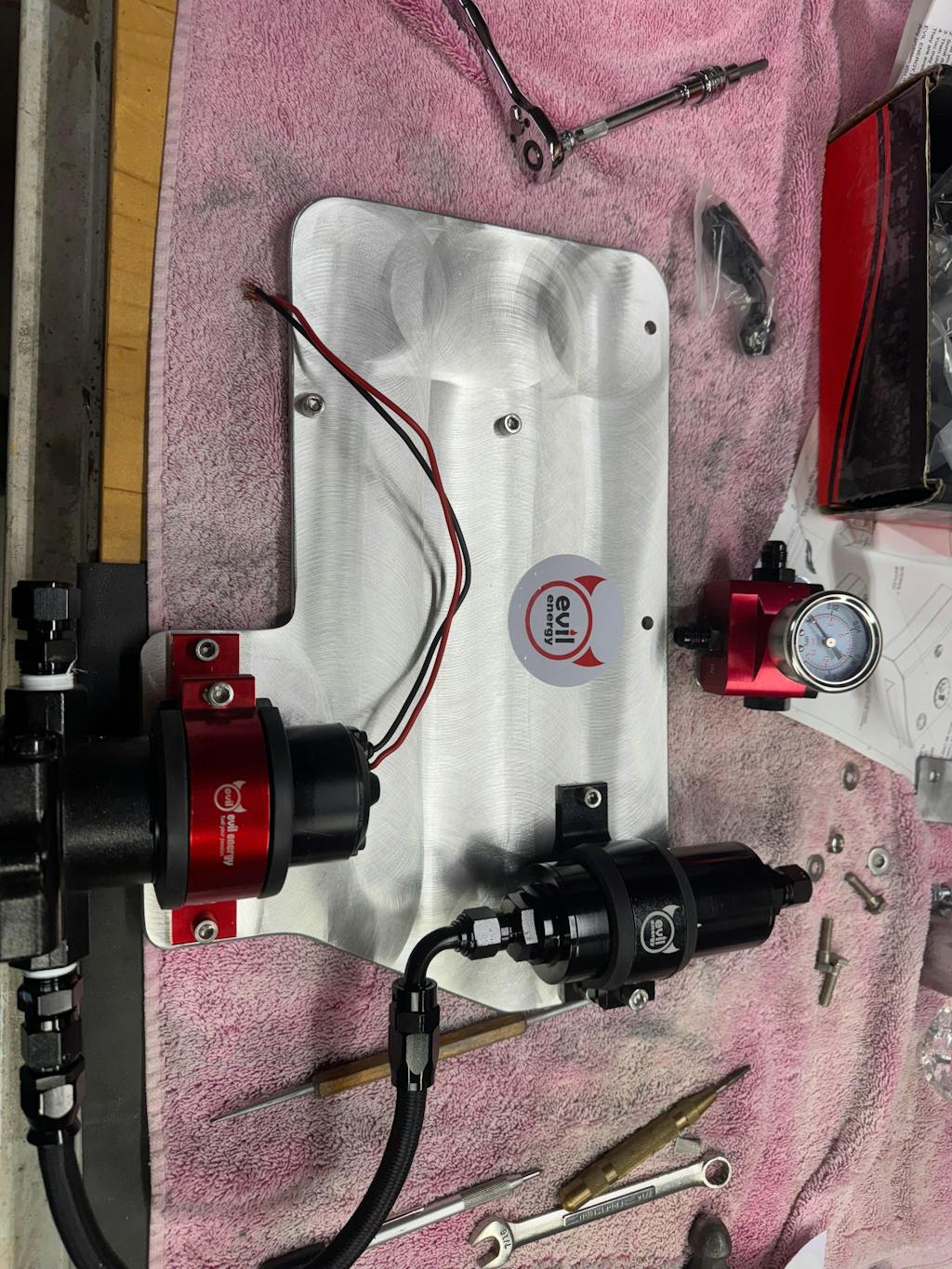

Evil Energy LS EFI System - Master Kit | Intake Manifold & Fuel Rail for Gen III LS1, LS2 | Inline Fuel Pump | Fuel Filter | PTFE Fuel Hose

- $826.68

- $826.68

$972.97- Unit price

- per

-

Evil Energy LS EFI System - Master Kit | Intake Manifold & Fuel Rail for GM LS3 L92 V8 6.2L | Inline Fuel Pump | Fuel Filter | PTFE Fuel Hose

- $648.18

- $648.18

$762.59- Unit price

- per

-

Evil Energy LS EFI System - Master Kit | Intake Manifold & Fuel Rail for GM LS1/LS2/LS6 | Inline Fuel Pump | Fuel Filter | PTFE Fuel Hose

- $622.59

- $622.59

$732.89- Unit price

- per

Get an Exclusive 8% Off Your First Purchase

Subscribe now to get a gift with your first order!

![[CPE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Fuel-Cell-Tank-Kit-Efficient-Fuel-System-Solutions-5-10-15-Gallon-EVIL-ENERGY-141125247_165x.jpg?v=1766341579)

![[PTFE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Fuel-Cell-Tank-Kit-Efficient-Fuel-System-Solutions-5-10-15-Gallon-EVIL-ENERGY-141125321_165x.jpg?v=1766341592)

![[30-70PSI,Red]](http://www.ievilenergy.com/cdn/shop/files/image_1_263dcd79-22f9-4671-ac88-9a91bf53d6df_165x.jpg?v=1768362974)

![[20-75PSI&75-120PSI]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Eco-Friendly-Fuel-Pressure-Regulator-6AN-EFI-Bypass-Return-Adjustable-30-70psi-Black_Red-EVIL-ENERGY-151921924_165x.png?v=1766347246)

![[LS Swap CPE Fuel Kit]](http://www.ievilenergy.com/cdn/shop/files/01_2_50504dbf-1a86-49d4-b5e7-8ef0be5de64f_165x.png?v=1770017164)

![[Fuel Filter Regulator Kit]](http://www.ievilenergy.com/cdn/shop/files/1_EVKT0202451_Fuel_Filter_Regulator_Kit_165x.webp?v=1770017164)

![[Fuel Rail Intake Manifold Bundle]](http://www.ievilenergy.com/cdn/shop/files/Fuel_Rail_Intake_Manifold_Bundle_165x.png?v=1736129679)

![[Fuel Rail]](http://www.ievilenergy.com/cdn/shop/files/2_323449ee-d9bc-4bf9-989c-2ef293bf1d22_165x.png?v=1735212247)

![[Fuel Rail +Intake Manifold Bundle]](http://www.ievilenergy.com/cdn/shop/files/Evil_Energy_intake_manifold_fuel_rail_165x.png?v=1735213573)

![[Intake Manifold]](http://www.ievilenergy.com/cdn/shop/files/Evil_Energy_intake_manifold_165x.png?v=1735213575)

![Evil Energy single plane intake manifold fuel rail [Fuel Rail +Intake Manifold Bundle]](http://www.ievilenergy.com/cdn/shop/files/Evil_Energy_single-plane_intake_manifold_fuel_rail_165x.png?v=1735213604)

![SuperVictorEFIIntakeManifoldwithFuelRailKitsforLS1_LS2

[Intake Manifold]](http://www.ievilenergy.com/cdn/shop/files/SuperVictorEFIIntakeManifoldwithFuelRailKitsforLS1_LS2_165x.png?v=1735213606)