Return vs. Returnless Fuel Systems: The Ultimate Guide for Performance Builds & LS Swaps

Choosing the right fuel system is a pivotal moment for any LS swap or high-performance project. The debate between a returnless fuel system and a return-style fuel system often comes down to balancing plumbing simplicity with fuel cooling efficiency. Whether you are searching for a return style fuel system diagram to map out your race car or modernizing a classic with an EFI conversion, understanding these flow dynamics is essential.

Understanding the Return Style Fuel System Diagram

A return-style fuel system is the gold standard for high-horsepower LS swaps and forced induction builds. By studying a return style fuel system diagram, you can see that the fuel pressure regulator is positioned after the fuel rails. This layout allows a return-style fuel system to constantly circulate fuel, which prevents the dreaded vapor lock in high-temperature engine bays.

In a typical return-style fuel system diagram, the path starts at the tank, goes through the pump and fuel filters, reaches the fuel rails, and the excess is sent back via a dedicated return line. For those performing an LS swap, using a return-style fuel system ensures that the fuel pressure stays consistent even under heavy load.

The Mechanics of a Returnless Fuel System

The returnless fuel system has become the primary industry standard for OEM manufacturers, largely due to its reduced plumbing complexity and lower evaporative emissions. Unlike a traditional return-style fuel system, which cycles fuel back to the tank from the engine bay, a returnless setup regulates fuel pressure at or near the fuel tank itself.

Return-Style vs. Returnless Layouts

Understanding the plumbing differences is crucial for any high-performance build:

-

Return-Style System: The fuel pressure regulator is mounted on the fuel rail. A primary feed line delivers fuel, and a second return line carries excess fuel back to the tank. This creates a constant 'loop' that keeps cool fuel circulating.

-

Returnless System: This is often called a 'deadhead' system. The pressure is regulated near the pump. Only the exact volume of fuel needed for combustion travels forward through a single supply line.

The 'Deadhead' Mechanism & The LS Swap

For enthusiasts performing a basic LS swap, the returnless configuration is the preferred choice because it significantly simplifies the chassis plumbing. However, the term 'returnless' is slightly misleading.

-

Internal Regulation: There is still a 'return' process, but it happens immediately at the pump or a chassis-mounted filter.

-

Pressure Maintenance: The pump sends fuel to the C5 Corvette filter regulator, which bleeds off excess pressure directly back into the tank through a short 2-foot line, rather than a 10-foot line from the engine.

-

The Single Feed: A single line carries the regulated 58 PSI (4 bar) of pressure to the LS fuel rails.

The Corvette C5 Filter Regulator Solution

The 1999–2004 Corvette C5 filter regulator is the 'gold standard' component for bridging the gap between a high-pressure EFI pump and an LS engine.

-

Inlet: Receives high-pressure fuel from the pump.

-

Return: Sends bypassed fuel back to the tank (regulating pressure to 58 PSI).

-

Outlet: Delivers clean, regulated fuel to the engine via a single 3/8-inch line.

Performance Trade-offs: The Heat Soak Factor

While a returnless fuel system is easier to install, it has a distinct disadvantage during track days or high-heat scenarios: Heat Soak.

In a returnless setup, fuel sits stagnant in the fuel rails above a hot intake manifold until an injector opens. This allows the fuel to absorb significant engine heat. In extreme conditions, this can lead to:

-

Inconsistent fuel pressure due to fuel expansion/vaporization.

-

Vapor lock in the rails.

-

Lean spikes during high-demand transitions.

| Feature | Returnless (C5 Style) | Return Style |

| Plumbing | Simple (1 line to engine) | Complex (2 lines to engine) |

| Cost | Low / Budget-friendly | High (Extra fittings & hose) |

| Fuel Cooling | Poor (Stagnant in rails) | Excellent (Constant flow) |

| Best Use | Street Rods / Daily LS Swaps | Turbo/Supercharged / Track Cars |

Optimization Summary

By utilizing the C5 Corvette filter regulator, you can maintain the 58 PSI required by the LS PCM without the headache of running dual fuel lines. However, if your build is destined for the road course, upgrading to a manifold-referenced return-style system is often worth the extra complexity to ensure stable fuel temperatures.

Why Upgrade to a Carburetor Return Style Fuel System?

Traditional carbureted setups were non-return (deadhead), meaning fuel stopped at the carburetor bowls. In contrast, a carburetor return-style fuel system ensures that cool fuel is constantly circulated from the tank to the engine and back again. This is the most effective way to modernize fuel delivery for classic muscle cars.

The Role of the Bypass Fuel Pressure Regulator

When studying a return-style fuel system diagram, the most critical component is the bypass fuel pressure regulator.

-

Protecting the Carburetor: High-volume electric fuel pumps can easily overpower the needle and seat of a classic carburetor.

-

Precision Control: The carburetor return style fuel system allows the regulator to 'bleed off' excess pressure and send it back to the fuel tank.

-

Consistent Pressure: This ensures the carburetor receives a steady 5-7 PSI, regardless of how hard the pump is working.

Eliminating Vapor Lock and Fuel Percolation

The primary reason enthusiasts switch to a carburetor return style fuel system is to combat vapor lock.

-

Heat Dissipation: In a deadhead system, stagnant fuel in the lines absorbs engine bay heat until it boils (percolation).

-

Constant Cooling: Because a carburetor return-style fuel system keeps fuel moving, the gasoline never stays in the engine bay long enough to reach its boiling point.

-

Summer Reliability: Integrating a return-style fuel system diagram into your classic's blueprints ensures your vehicle remains reliable during extreme summer heat or stop-and-go traffic.

Comparison: Deadhead vs. Carburetor Return Style Fuel System

| Feature | Deadhead (Non-Return) | Carburetor Return Style Fuel System |

| Fuel Temperature | High (Stagnant fuel absorbs heat) | Low (Constant circulation) |

| Vapor Lock Risk | High | Extremely Low |

| Regulator Type | Standard Blocking Regulator | Bypass Fuel Pressure Regulator |

| Pump Longevity | Lower (Pump works against a wall) | Higher (Pump runs cooler/freer) |

| Best For | Low-budget street cruisers | High-performance / Pro-Touring builds |

Implementation for Classic Chevy and Ford Builds

Whether you are plumbing a small-block Chevy or a Ford FE engine, the carburetor return style fuel system is the professional choice. By using a return-style fuel system diagram, you can accurately map out the 3/8-inch supply and return lines needed to support high-horsepower applications without the risk of leaning out or flooding the bowls.

Key Components: PTFE Fuel Lines and Regulators

No LS swap is complete without the right hardware. When following a return-style fuel system diagram, your choice of plumbing matters. PTFE fuel lines are highly recommended for any LS swap or carburetor return-style fuel system because they are compatible with E85 and resist fuel odors.

Whether you are building a returnless fuel system or a return-style fuel system, high-quality fuel pressure regulator kits are vital. A vacuum-referenced regulator in a return-style fuel system allows for a 1:1 ratio adjustment, which is a feature you won't find in a standard returnless fuel system.

Technical Comparison Table

| Feature | Return Style Fuel System | Returnless Fuel System |

| Ideal Build | LS Swap (Turbo/Supercharged) | LS Swap (Daily Driver) |

| Diagram Type | Return style fuel system diagram | Single-line fuel diagram |

| Vapor Lock Risk | Extremely Low | Moderate to High |

| Plumbing | Dual PTFE fuel lines | Single feed line |

| PSI Control | High (Vacuum-referenced) | Static (Tank-regulated) |

Summary for Your LS Swap

For a high-performance LS swap, a return-style fuel system is the superior choice for managing heat and fuel pressure. If you are on a budget, a returnless fuel system might suffice, but always refer back to a return-style fuel system diagram if you plan on adding boost later. From PTFE fuel lines to carburetor return style fuel system setups, EVIL ENERGY provides the professional-grade components needed to complete your LS swap with confidence.

Shop High-Performance Fuel System Components

Professional-grade parts for LS Swaps, EFI Conversions, and Classic Builds.

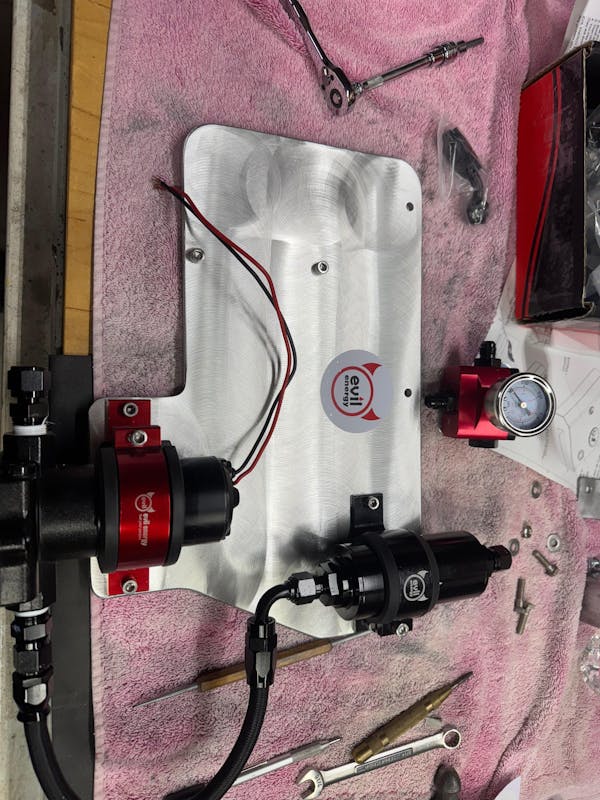

Fuel Pump Kits & Assemblies

Fuel Filters & Accessories

Fuel Pressure Regulator Kits

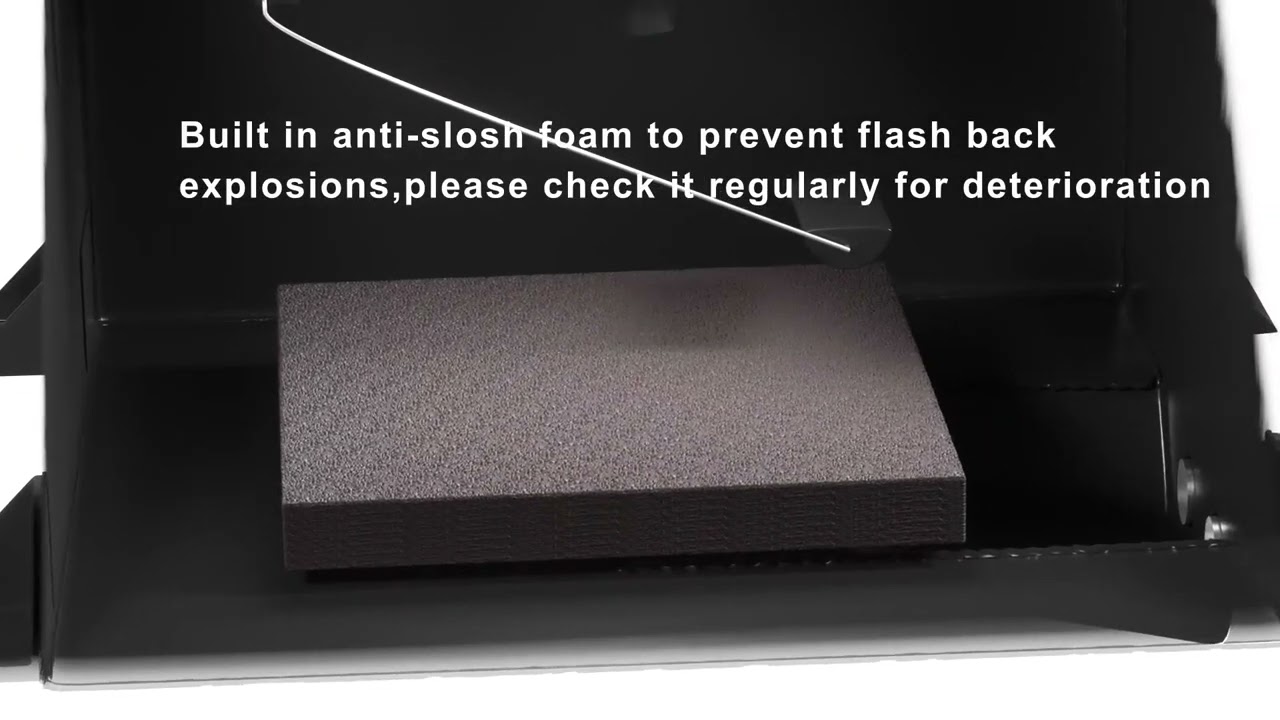

Fuel Cells & Tank Accessories

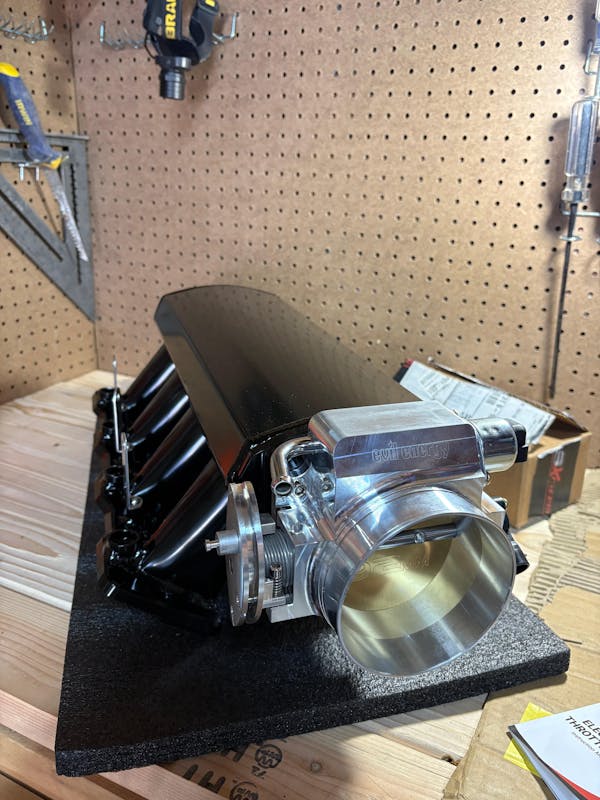

Fuel Rails & Manifold Kits

Carburetor Systems

Advanced Reading & Expert Guides

Mastering your fuel delivery is the key to a reliable, high-performance build. Whether you are troubleshooting a vapor lock issue or planning a full EFI conversion, explore these deep-dive guides to finalize your project:

System Foundations & Visual Overviews

- The Ultimate Visual Guide to Your Car’s Fuel System & Tank Anatomy – A must-read for understanding how every component from the filler neck to the fuel rail works together.

- Understanding the Fuel Injection System: Function, Types, and Maintenance

Fuel Tanks & Plumbing (Essential for LS Swaps)

- 15 Gallon Fuel Cell & PTFE Fuel Lines Guide: Size, Fitment, Hose & AN Fittings

- How Does a Fuel Cell Work? A Deep Dive into Racing Fuel Cells

Carburetor Selection & Tuning (Classic Chevy/Ford Owners)

- How to Choose the Right Carburetor for a Chevy 350 (SBC) Engine

- 650 CFM vs 750 CFM Carburetor: Why Bigger Isn't Always Better

- 500 CFM vs 650 CFM: Choosing Between Cruising Economy and Street Performance

- Holley VS EVIL ENERGY: Which 350 CFM Carburetor is Best for a 350 Chevy?

- The Ultimate 650 CFM Carburetor Guide: Choosing the Best Model for Your Engine

- How to Tune Your C/K Truck's Carburetor to Eliminate Cold Start Problems

Model-Specific Maintenance

FAQs About Your LS Swap

Q1: Why should I use a return-style fuel system diagram for my LS swap?

A: Using a return-style fuel system diagram is essential for any high-performance LS swap because it ensures a constant circulation of cool fuel. Unlike a static setup, a return-style fuel system uses a fuel pressure regulator positioned after the rails, preventing heat soak and maintaining consistent fuel pressure even under extreme racing conditions.

Q2: Is a returnless fuel system sufficient for a turbocharged LS swap?

A: While a returnless fuel system is simpler to install, it is generally not recommended for turbocharged LS swaps. Forced induction requires a vacuum-referenced return style fuel system to adjust fuel pressure in a 1:1 ratio with boost. Without the logic shown in a return-style fuel system diagram, you risk lean spikes and potential engine damage.

Q3: What are the main benefits of a carburetor return-style fuel system?

A: A carburetor return-style fuel system eliminates the common issue of vapor lock in classic cars. By following a carburetor return style fuel system diagram, you can implement a bypass regulator that keeps fuel moving back to the tank, ensuring the fuel in your lines stays cool and doesn't boil in the engine bay during high-temperature operation.

Q4: Can I convert a returnless fuel system into a return-style fuel system?

A: Yes, you can convert a returnless fuel system by adding a return line and an external fuel pressure regulator. Most enthusiasts performing an LS swap start with a return-style fuel system diagram to plan the plumbing with PTFE fuel lines, which are necessary for handling higher flow rates and modern E85 fuel blends.

Q5: Why do experts recommend PTFE fuel lines for a return-style fuel system?

A: PTFE fuel lines are the gold standard for any return-style fuel system or LS swap. Unlike standard rubber hoses, PTFE fuel lines do not degrade when exposed to ethanol-blended fuels and effectively block fuel vapors, ensuring your garage doesn't smell like raw gasoline.

Q6: How does a vacuum-referenced regulator work in a return-style fuel system diagram?

A: In a return-style fuel system diagram, the vacuum-referenced regulator is connected to the intake manifold. It adjusts the fuel pressure based on the engine's load and manifold pressure. This is a critical feature for LS swap projects that need precise air-fuel ratios across varying RPM ranges and boost levels.

Q7: What is the most common mistake in a carburetor return-style fuel system setup?

A: The most common mistake is placing the regulator too far from the carburetor. A proper carburetor return style fuel system diagram will show the bypass regulator mounted close to the carb to ensure the fuel pressure remains stable and the needles and seats are not overwhelmed by the fuel pump's volume.

Q8: Does a return-style fuel system require a different type of fuel pump?

A: A return-style fuel system typically requires a high-volume electric fuel pump capable of maintaining high pressure. Whether you are building a returnless fuel system or a return-style fuel system, you must ensure the pump's LPH (Liters Per Hour) rating matches your horsepower goals as outlined in your LS swap technical plans.

Q9: Will a return-style fuel system help with hot start issues?

A: Absolutely. A return-style fuel system significantly reduces hot start issues by flushing out hot fuel and vapor from the feed lines. By following a return style fuel system diagram, you ensure that fresh, cool fuel from the tank is always available at the injectors or carburetor for immediate, reliable ignition.

![[20FT] EVIL ENERGY PTFE Fuel Line Kit, complete black hose & fittings set, 180-day return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598065_165x.png?v=1742144807)

![[16FT] EVIL ENERGY PTFE Fuel Line Kit, black braided hose, fittings, free shipping & return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598171_165x.png?v=1742144807)

![CPE Fuel Line[25FT]](http://www.ievilenergy.com/cdn/shop/files/25FTCPE_FuelLine_165x.png?v=1735220649)

![CPE Fuel Line[20FT]](http://www.ievilenergy.com/cdn/shop/files/20FTCPE_FuelLine_165x.png?v=1735220649)