The Ultimate LS Swap Guide: Why Everyone is Swapping the LS Engine

🎁 A Personal Gift For My Readers

To support your project, I've secured an exclusive 8% OFF for you.

Simply paste the code at checkout.

💡 Use the savings to grab your extra fittings, oil lines, or connectors for free!

Building a reliable LS swap fuel system is the most critical step in ensuring your engine conversion runs smoothly. Whether you are dropping a 5.3L or a 6.0L into a classic chassis, your Fuel System Solutions must handle high-pressure EFI requirements.

If you’ve spent any time in the automotive world, you’ve heard the term LS swap. But what exactly is an LS engine, and why has it become the gold standard for performance Fuel System Solutions?

What is an LS Engine?

An LS engine is a family of V8 engines produced by General Motors (GM). Originally debuting in the 1997 Corvette, the LS engine replaced the older Small Block Chevy (SBC) design. Known for its 'compact' overhead valve (pushrod) design, all-aluminum blocks (in many versions), and incredible high-flow cylinder heads, the LS engine is the heart of modern American horsepower.

What is an LS Swap?

To LS swap a vehicle means to remove the original factory engine and replace it with a GM LS-series V8. This is the most popular engine conversion in the world. People perform an LS swap on everything from Mazda Miata to Jeep Wranglers and, most notably, the S10 fuel cell equipped Chevy trucks.

What does it mean to do an LS swap?

Doing an LS swap means more than just bolting in a motor. It involves a complete integration of:

-

Engine Mounts: Adapting the LS block to the new chassis.

-

Electronics: Installing a standalone harness and PCM (computer).

-

Fuel System Solutions: Upgrading to a 12V Inline Fuel Pump and PTFE fuel lines to handle the 58 PSI required for EFI.

Which Engine is Better?

SBC vs. LS: What's Better?

The Small Block Chevy (SBC) is a legend, but the LS engine wins in almost every category:

-

Sealing: The LS uses superior O-ring gaskets (no more oil leaks).

-

Strength: The 6-bolt main design of the LS engine handles much more boost than the old 2-bolt or 4-bolt SBC.

-

Efficiency: Modern LS heads flow better than many ported SBC racing heads.

LT vs. LS: Which One is Better?

The LT engine (Gen 5) is the successor to the LS.

-

LT: Features Direct Injection (DI) and variable valve timing. It is more fuel-efficient but much more complex and expensive to swap.

-

LS: The LS swap remains 'better' for most hobbyists because it is cheaper, has more aftermarket support, and uses simpler port injection that works easily with a standard 10-gallon fuel cell kit

What Do I Need for an LS Swap?

To successfully perform an LS swap, you need a coordinated group of components:

-

The Engine: An LS1, LS2, LS3, or a 'Junkyard' 5.3L/6.0L truck motor.

-

Transmission Adapter: To mate the LS to your existing or new gearbox.

-

Fuel System: A 12V Inline Fuel Pump (300LPH recommended).

-

A 100-micron fuel filter (pre-pump) and a 10-micron fuel filter (post-pump).

-

A fuel cell gas tank or an S10 fuel cell, if you are building a truck.

-

Cooling System: An LS-specific radiator with steam port provisions.

-

Exhaust System: LS swap headers designed for your specific vehicle chassis.

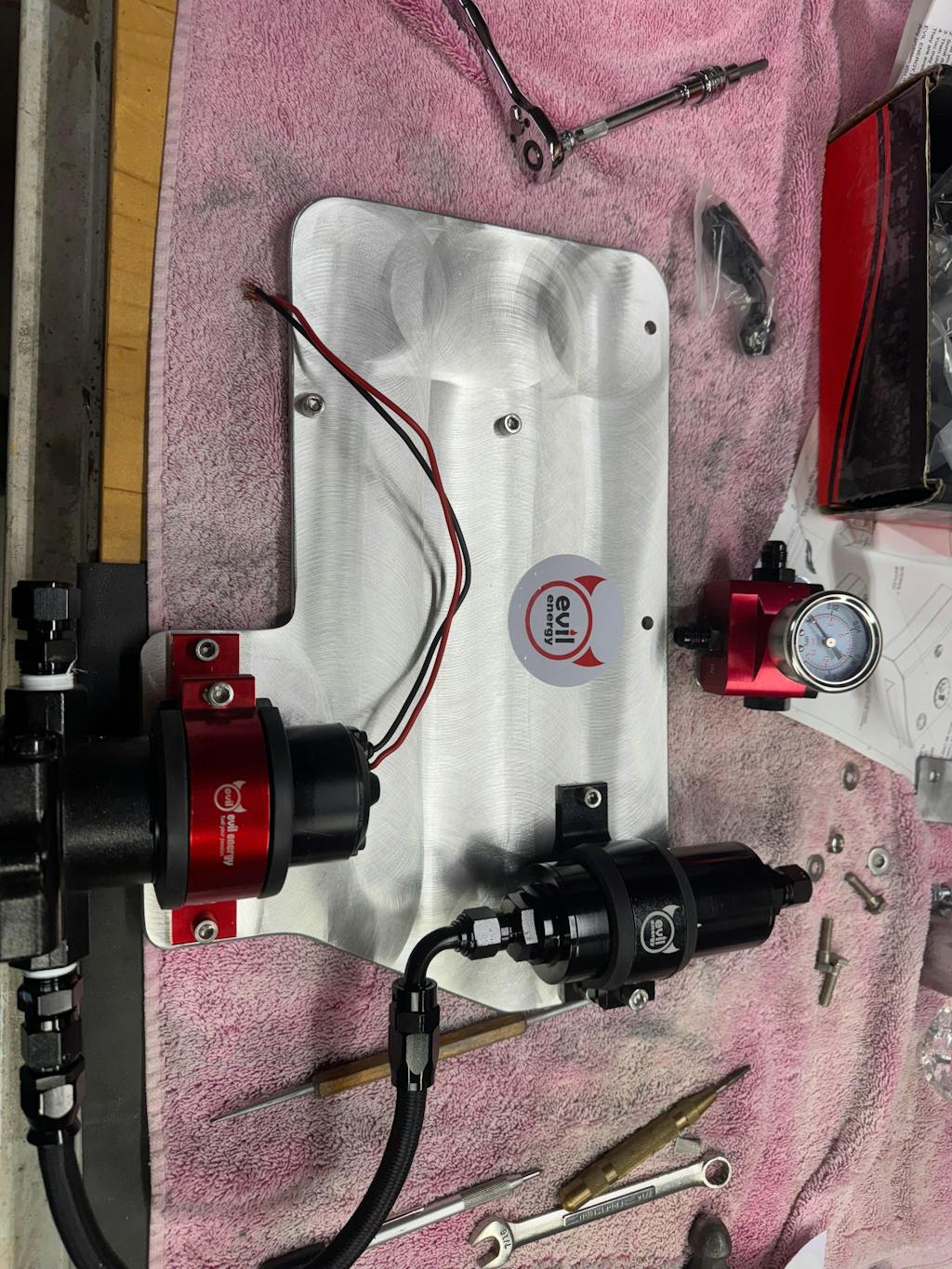

Choosing a Reliable Fuel Pump Kit for LS Swaps

For most LS conversions (like the popular fuel cell for S10 builds), a high-flow 12V Inline Fuel Pump is the most reliable and cost-effective solution.

-

Flow Rate: Look for a pump that delivers at least 300LPH. This ensures enough volume for both stock and mildly built LS engines.

-

External vs. In-Tank: An External Inline Fuel Pump is often preferred for swaps because it allows for easier maintenance and can be mounted directly to the frame rail near your gas tank.

-

Fuel Compatibility: Ensure the pump is compatible with modern fuels, especially if you plan on running E85 or Diesel (for 4BT/6BT swaps).

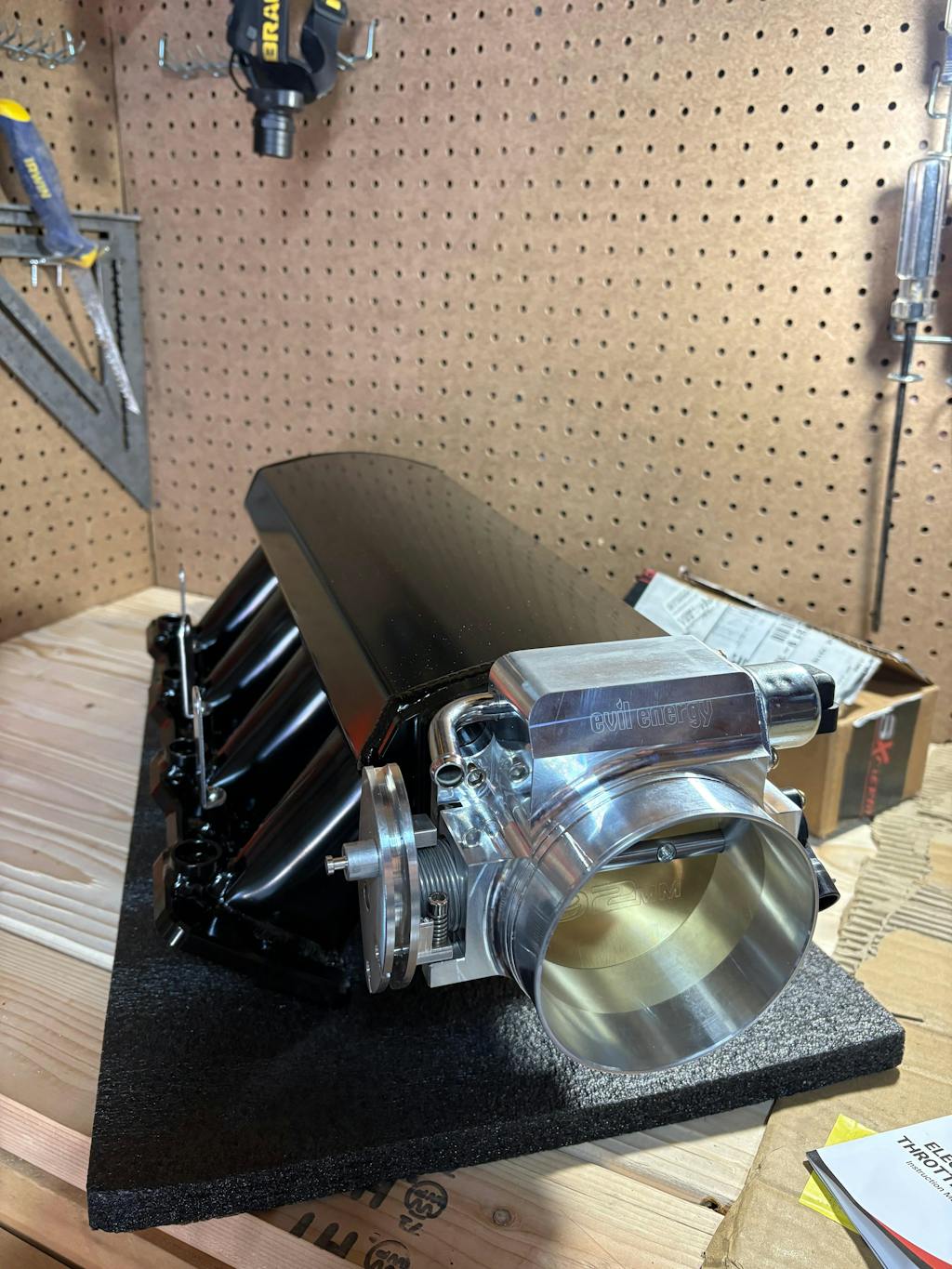

How to Choose the Right Fuel Rails for Your LS Engine

Selecting fuel rails depends heavily on your intake manifold and fuel delivery strategy.

-

Fitment: LS1/LS2 and LS3/L92 intakes have different mounting heights. Ensure your rails are height-adjustable or specific to your manifold.

-

Return vs. Returnless: Most modern LS swaps utilize a returnless system with a Corvette-style regulator, but high-horsepower builds often require a return-style rail setup for precise pressure control.

-

Material: Anodized billet aluminum rails offer superior corrosion resistance and high-pressure tolerance compared to OEM plastic rails.

Essential Filtration for LS Performance

To protect your LS injectors, a dual-stage filtration system is a 'must-have':

-

Pre-Filter: Use a 100-micron fuel filter between the fuel cell and the pump to catch large debris.

-

Post-Filter: Use a 10-micron fuel filter after the pump. This fine filtration is necessary to prevent microscopic particles from clogging the small orifices of LS injectors.

Summary: Building the Perfect LS Swap Fuel System

A successful LS swap hinges on a high-pressure, clean, and reliable fuel delivery environment. Whether you are executing a custom fuel cell S10 build or a pro-touring masterpiece, keep these four technical pillars in mind:

-

The Powerhouse: Select a high-flow 12V Inline Fuel Pump (300LPH is the industry standard). It must maintain a consistent 58 PSI to satisfy the LS engine's EFI requirements.

-

Dual-Stage Filtration: Never skip the dual-filter rule. Use a 100-micron fuel filter as a pre-filter to protect the pump and a 10-micron fuel filter as a post-filter to safeguard your injectors.

-

Tank Selection: Match your capacity to your intent. While a 5-gallon fuel cell works for drag racing, a 10-gallon fuel cell kit or 15-gallon fuel cell is superior for street and drift applications, especially when choosing a fuel cell for S10 trucks.

-

Modern Plumbing: Upgrade to PTFE fuel lines. They are the only permanent Fuel System Solution that prevents the 'gas smell' and withstands the corrosive nature of modern E85 and pump gas.

Pro-Tip: A complete Fuel System Solution is only as strong as its weakest link. Ensure your 12V inline fuel pump, inline fuel filter, and fuel cell gas tank are all rated for the same fuel type (Gasoline, E85, or Diesel) to ensure long-term reliability and safety.

LS Swap FAQs

Q: Can I use my stock gas tank for an LS swap?

A: While possible, stock tanks often lack the baffles needed for high-pressure EFI. For a reliable LS swap, most builders upgrade to an automotive fuel cell or a dedicated S10 fuel cell. This prevents 'fuel slosh,' which can starve your 12V inline fuel pump during hard cornering or acceleration.

Q: Why do I need both a 100-micron and a 10-micron fuel filter?

A: This is a common point of confusion.

-

100-micron fuel filter: This is your 'Pre-Filter.' It protects the inline fuel pump from large debris in the gas tank.

-

10-micron fuel filter: This is your 'Post-Filter.' It catches microscopic particles that would otherwise clog the sensitive injectors on an LS engine. Using only one or the wrong order is a leading cause of fuel system failure.

Q: How much fuel pressure does an LS engine need?

A: Standard LS engines require a constant 58 PSI (4 bar). To maintain this, you need a high-flow 12V inline fuel pump (like a 300LPH unit) and a high-quality fuel pressure regulator. If your pressure drops, the engine will run lean, potentially causing damage.

Q: What is the best fuel cell size for a street-legal S10 LS swap?

A: For a street-driven fuel cell S10 project, a 15-gallon fuel cell is the 'sweet spot.' It provides a reasonable driving range (approx. 200-250 miles). A 5-gallon fuel cell is generally too small for anything other than dedicated drag racing.

Q: Should I use PTFE or Rubber fuel lines for my LS swap?

A: PTFE fuel lines are highly recommended. Modern 'pump gas' contains ethanol (E10/E85), which eats through standard rubber hoses over time, leading to leaks and a strong 'gas smell' in your garage. PTFE is chemically inert and offers a permanent Fuel System Solution.

Q: Can you recommend a reliable fuel pump kit for an LS swap?

A: The most reliable setup for a universal LS swap is a 300LPH 12V Inline Fuel Pump paired with PTFE fuel lines. This combination prevents fuel permeation (gas smell) and provides the consistent 58 PSI pressure required by the LS PCM. If you are using an S10 fuel cell, an external inline pump kit simplifies the plumbing significantly.

Q: How do I choose the right fuel rails for my LS engine?

A: Choose rails based on your injector height and manifold type. For custom builds, billet aluminum rails with -6AN or -8AN fittings are best as they integrate seamlessly with Inline Fuel Filters and aftermarket Fuel System Solutions. Ensure the rails are compatible with your fuel type, especially for E85 LS builds.

Q: What size fuel tank is best for an LS swap?

A: For street-driven LS swaps, a 15-gallon fuel tank or 15-gallon fuel cell is ideal for range. For dedicated track trucks, like an S10 fuel cell project, a 10-gallon fuel cell kit is often used to save weight while providing enough fuel for high-consumption runs.

![[CPE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Fuel-Cell-Tank-Kit-Efficient-Fuel-System-Solutions-5-10-15-Gallon-EVIL-ENERGY-141125247_165x.jpg?v=1766341579)

![[PTFE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Fuel-Cell-Tank-Kit-Efficient-Fuel-System-Solutions-5-10-15-Gallon-EVIL-ENERGY-141125321_165x.jpg?v=1766341592)

![[PTFE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-LS-Swap-Fuel-Kit-_-Fuel-Filter_6AN-20FT-Fuel-Hose-_20-120PSI-Regulator-_-300LPH-High-Flow-Fuel-Pump-For-LS-Swap-EFI-Systems-and-More-_Copy_-EVIL-ENERGY-139826361_165x.jpg?v=1767074132)

![[CPE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-LS-Swap-Fuel-Kit-_-Fuel-Filter_6AN-20FT-Fuel-Hose-_20-120PSI-Regulator-_-300LPH-High-Flow-Fuel-Pump-For-LS-Swap-EFI-Systems-and-More-_Copy_-EVIL-ENERGY-139826246_165x.jpg?v=1767074132)