Mastering the LS Swap Fuel System: The Professional Guide to Pumps, Lines & EFI

🎁 A Personal Gift For My Readers

To support your project, I've secured an exclusive 8% OFF for you.

Simply paste the code at checkout.

💡 Use the savings to grab your extra fittings, oil lines, or connectors for free!

Building an LS-powered beast requires more than just a motor; it requires a high-pressure LS swap fuel system capable of supporting modern fuel injection. Unlike vintage carbureted engines that run on 5-9 PSI, a complete LS fuel system must maintain a constant 58 PSI to feed the hungry injectors of an LS1, LS3, or L92. Choosing the best fuel pump for LS swap projects is the difference between consistent power and a lean-condition disaster. Whether you are searching for an LS swap fuel pump kit for a classic truck or a drift car, this guide covers every component from the tank to the torque.

Understanding the LS Fuel System: How It Works

Every internal combustion engine follows the four-stroke cycle, but the LS platform adds a layer of complexity with its electronic fuel injection (EFI). To ensure your LS swap fuel pump kit functions correctly, you must understand the flow:

-

Sourcing: The LS fuel pump pulls fuel from the tank.

-

Filtration & Regulation: A regulator maintains the 58 PSI required for the LS fuel line.

-

Delivery: Fuel travels through an LS swap fuel line to the fuel rails.

For those transitioning from older technology, our guide on Carburetor to Electric Fuel Pump Conversion provides essential context.

Core Components: The LS Swap Fueling Blueprint

To simplify your project, most builders opt for a complete LS swap fuel system kit. This ensures compatibility across all fittings and lines.

-

Choosing the Best Fuel Pump for LS Swap

The 'heart' of your building is the pump. You have two primary paths: In-tank or External. Use the comparison table below to determine which LS swap fuel pump kit fits your chassis.

|

Feature

|

In-Tank Solution

|

External/Inline Solution

|

|

Search Term

|

best in-tank fuel pump for LS swap

|

best external fuel pump for LS swap

|

|

Typical Kit

|

LS swap fuel pump kit (In-tank)

|

ls swap inline fuel pump kit

|

|

Cooling

|

Excellent (Fuel-submerged)

|

Moderate (Air-cooled)

|

|

Noise Level

|

Very Low (Insulated by tank)

|

Higher (Frame-mounted)

|

|

Installation

|

Complex (Tank modification)

|

Simple (Splice into the LS fuel line)

|

|

Best Use Case

|

Daily Drivers, High-HP Street Cars

|

Racing, Budget EFI Retrofits

|

Explore our detailed breakdown of Inline & In-Tank Solutions to find your perfect match.

-

Plumbing with LS Fuel Line Kits

Standard rubber hoses won't cut them. You need a dedicated LS fuel line kit featuring PTFE or reinforced nylon. An LS swap fuel line kit often includes the necessary LS fuel line adapter kit to connect factory fuel rails to aftermarket AN fittings.

LS Swap Fueling Essentials Checklist

When searching for the right LS swap fuel system kit, ensure you have these five mandatory components.

|

Component

|

Primary Function

|

Relevant Keyword

|

Essentiality

|

|

Fuel Pump Kit

|

Provides constant 58 PSI pressure

|

LS swap fuel pump kit

|

100% Mandatory

|

|

Fuel Lines

|

High-pressure transport; E85 safe

|

LS swap fuel line kit

|

100% Mandatory

|

|

Adapters

|

Connects OEM rails to AN lines

|

LS fuel line adapter kit

|

100% Mandatory

|

|

Inline Pump

|

Ideal for external frame-mounting

|

In-line fuel pump for LS swap

|

Setup Dependent

|

|

Flex Sensor

|

Adjusts tuning for ethanol content

|

LS fuel system (E85)

|

Optional Upgrade

|

The Great Debate: Return vs. Returnless Systems

-

Return System: Uses a dedicated LS swap fuel line to send excess fuel back to the tank.

-

Returnless System: Uses a manifold-referenced regulator (like the C5 Corvette style) near the tank to simplify the LS1 swap fuel line kit layout.

For a full vehicle integration strategy, refer to The Complete LS Swap Kit Guide.

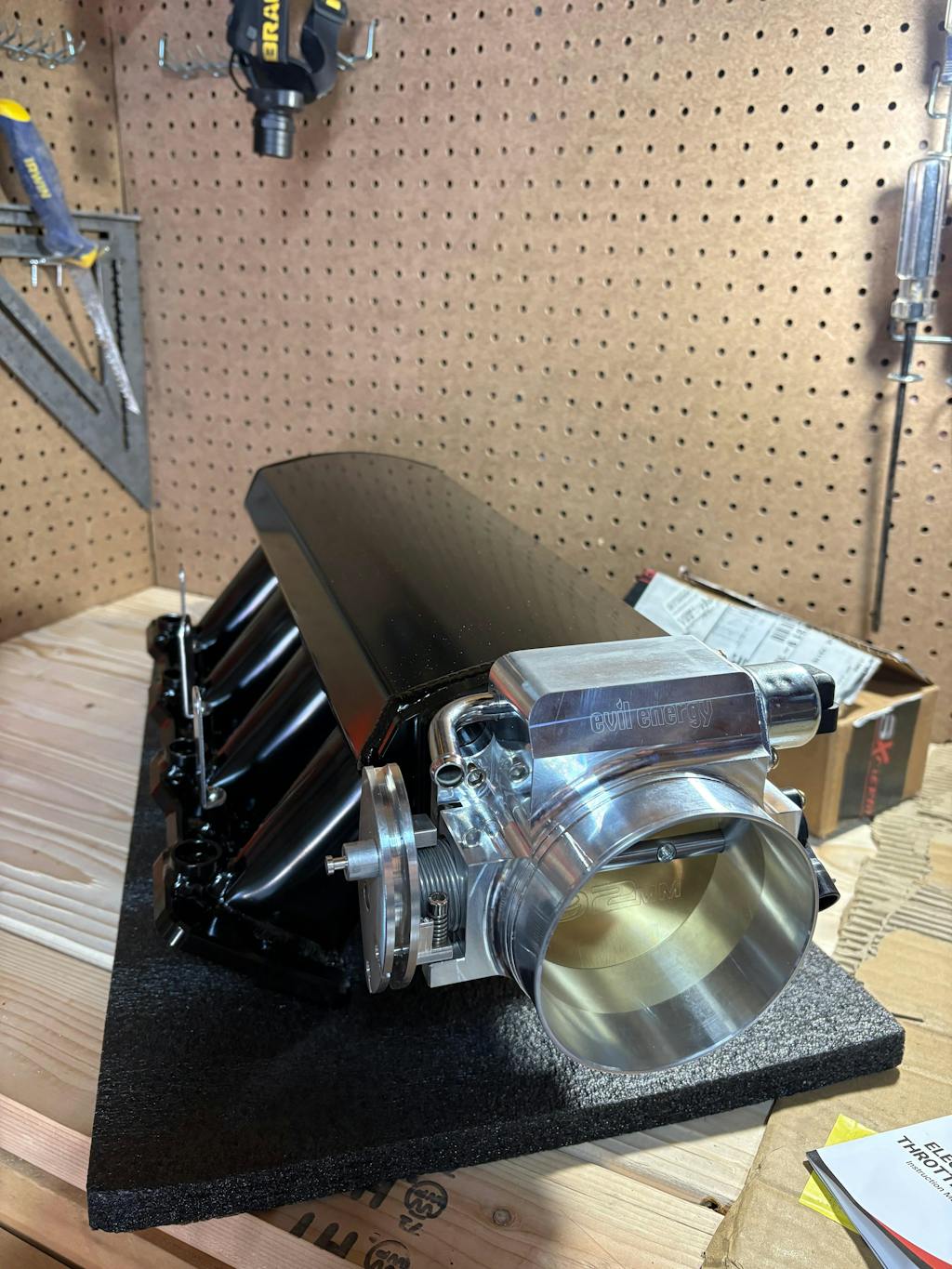

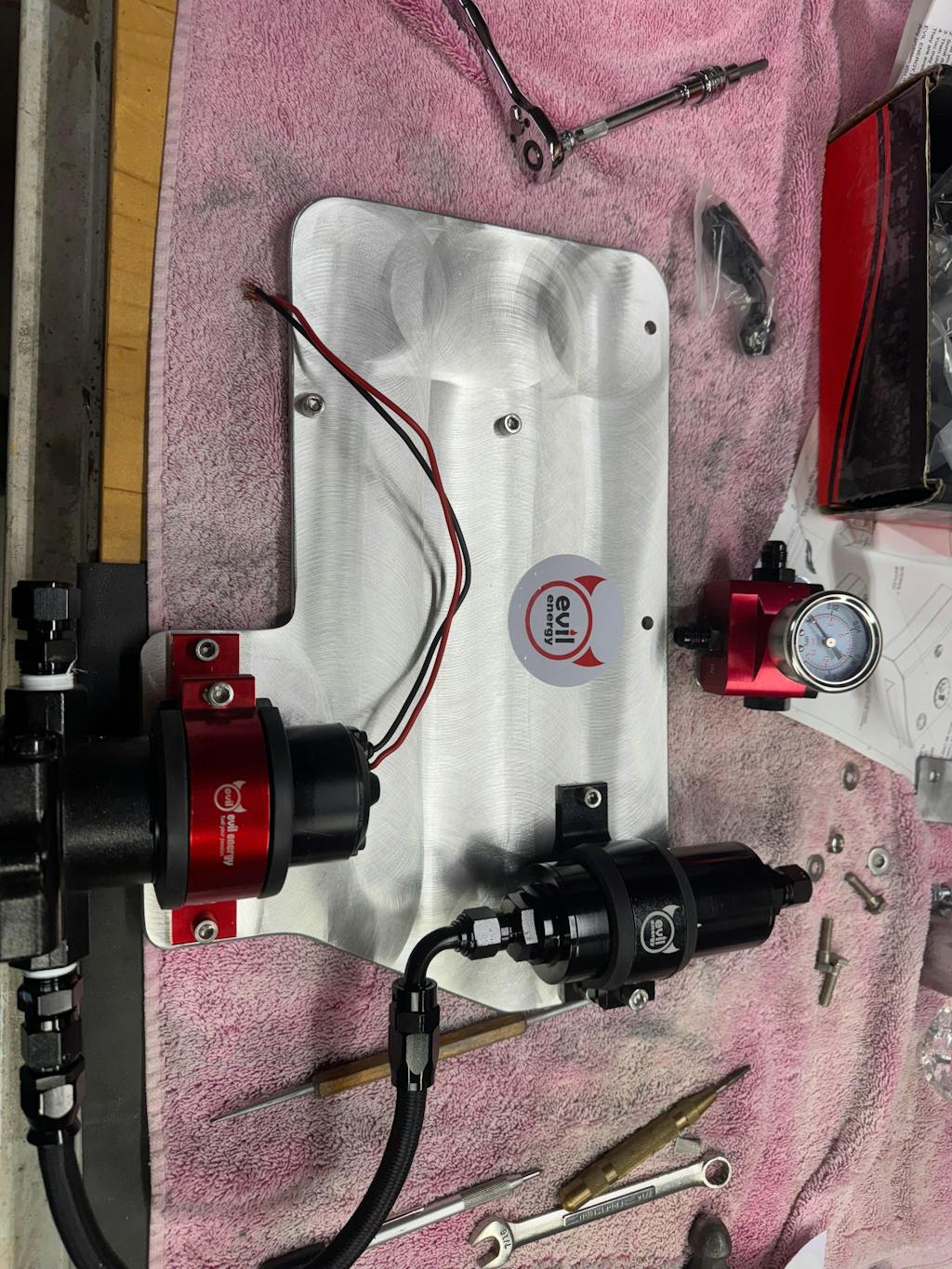

Why Choose EVIL ENERGY for Your LS Fuel System?

Building an LS1 swap fuel pump kit or a massive LS3 swap demands racing-grade hardware. Our LS swap fuel kit solutions are CNC-machined and pressure-tested to handle E85. If you are aiming for maximum performance, don't forget to check our E85 Flex Fuel Guide: Unlock 100+ Octane Power.

Conclusion: Ready to Fuel Your Dream?

From the best fuel pump for LS swap to the final LS fuel line connection, every part matters. Don't let a weak LS fuel pump hold back your V8. Shop our Complete EFI Fuel System Kits and simplify your motor swap project today with the Ultimate Engine Conversion Kits.

FAQs: LS Swap Fuel Systems & Component Selection

Q1: What is the required fuel pressure for an LS swap fuel system?

A: A standard LS fuel system requires a constant 58 PSI (4 bar) of fuel pressure. Unlike older carbureted engines, the LS series uses high-pressure electronic fuel injection (EFI). To maintain this, you must use a high-performance LS fuel pump and a compatible regulator, often found in a complete LS swap fuel system kit.

Q2: Should I choose an in-tank or an in-line fuel pump for LS swap projects?

A: The best in-tank fuel pump for LS swap builds offers superior cooling and quieter operation because the fuel muffles the sound and absorbs heat. However, an in-line fuel pump for LS swap is often preferred for budget-friendly retrofits or racing applications where the fuel tank cannot easily be modified to accept a modern LS swap fuel pump kit.

Q3: Why is an LS fuel line adapter kit necessary?

A: An LS fuel line adapter kit is essential because factory GM fuel rails use specific quick-connect fittings (typically 3/8-inch or 5/16-inch). Most aftermarket LS swap fuel line kit solutions use AN-6 or AN-8 braided lines. The adapter kit bridges this gap, ensuring a leak-free connection between the rail and your custom LS fuel line.

Q4: Can I use standard rubber hoses for my LS swap fuel line?

A: No. Standard rubber hoses will degrade quickly under high pressure and modern ethanol-blended fuels. You must use a dedicated LS swap fuel line made from PTFE or reinforced Nylon. Investing in a professional LS swap fuel line kit ensures your plumbing can handle the 58 PSI requirements and chemical properties of modern pump gas.

Q5: What is included in a complete LS swap fuel pump kit?

A: A professional LS swap fuel pump kit typically includes a high-flow electric pump (255LPH or higher), a fuel filter/regulator (often the C5 Corvette style), mounting brackets, and the necessary wiring harness. Some premium LS1 swap fuel pump kit options also include the sub-harness for easy integration with the engine computer.

Q6: What is the difference between a return and a returnless LS swap fuel kit?

A: A return-style ls swap fuel kit uses two lines: one for delivery and one to return excess fuel to the tank. A returnless system uses a regulator located near the tank to simplify the LS1 swap fuel line kit layout, requiring only a single LS fuel line to run forward to the engine bay.

Q7: Is an external fuel pump for LS swap builds reliable for daily driving?

A: Yes, but mounting is key. An external fuel pump for an LS swap must be mounted lower than the lowest point of the fuel tank because these pumps are designed to push fuel, not pull it. For long-term street reliability, ensure your LS swap external fuel pump kit is protected from road debris and excessive heat.

Q8: How do I select the best fuel pump for LS swap high-horsepower builds?

A: To choose the best fuel pump for LS swap builds exceeding 500HP, you should look at the liters per hour (LPH) rating. An LS1 fuel pump kit with a 340LPH or dual-pump setup is often required. Always ensure your LS fuel line kit is sized correctly (AN-8) to support the increased volume.

Q9: Do I need a specific LS1 swap fuel line kit for E85 fuel?

A: Yes. E85 is highly corrosive to standard materials. If you plan to run ethanol, ensure your LS swap fuel line kit is PTFE-lined. Many builders starting an LS1 swap fuel pump kit project overlook this, but using E85-rated components from the start prevents future system failure.

Q10: Why should I buy a complete LS swap fuel system kit instead of piecing it together?

A: Buying a complete LS swap fuel system kit ensures that every fitting, line, and pump is compatible. Piecing together an LS fuel system often leads to mismatched thread pitches or incorrect LS fuel line adapter kit sizes, which can cause dangerous leaks and fuel pressure drops during operation.

![[CPE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Fuel-Cell-Tank-Kit-Efficient-Fuel-System-Solutions-5-10-15-Gallon-EVIL-ENERGY-141125284_165x.jpg?v=1771520007)

![[PTFE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Fuel-Cell-Tank-Kit-Efficient-Fuel-System-Solutions-5-10-15-Gallon-EVIL-ENERGY-141125347_165x.jpg?v=1771520008)

![[PTFE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-LS-Swap-Fuel-Kit-_-Fuel-Filter_6AN-20FT-Fuel-Hose-_20-120PSI-Regulator-_-300LPH-High-Flow-Fuel-Pump-For-LS-Swap-EFI-Systems-and-More-_Copy_-EVIL-ENERGY-139826346_165x.jpg?v=1771519881)

![[CPE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-LS-Swap-Fuel-Kit-_-Fuel-Filter_6AN-20FT-Fuel-Hose-_20-120PSI-Regulator-_-300LPH-High-Flow-Fuel-Pump-For-LS-Swap-EFI-Systems-and-More-_Copy_-EVIL-ENERGY-139826278_165x.jpg?v=1771519878)