HOSE BARB FITTINGS: SMART SOLUTIONS FOR DESIGN, INSTALLATION, AND APPLICATIONS

HOSE BARB FITTINGS: SMART SOLUTIONS FOR DESIGN, INSTALLATION, AND APPLICATIONS

Hose Barb Fittings, sometimes referred to as barbed fittings or hose barbed connectors, play a crucial role in fluid and gas flow systems due to their cost-effectiveness, efficiency, and widespread availability. Hose Barb Fittings find applications ranging from biopharmaceutical procedures to connecting garden hoses. While hose carb fittings are commonly used, people still have a pressing need to have a thorough understanding of performance and proper sizing. So, without delay, let’s delve into this more!

Mastering Fluid Transfer with Hose Barb Fittings

To master fluid transmission with Hose Barbed Fittings, one must carefully select the fitting size material and install it to prevent leaks while maximizing efficiency. When it comes to transferring fluids, hoses, and tubes can be easily connected using hose barb fittings, designed to prevent fluid leakage and ensure efficient fluid transfer.

When mastering fluid transfer with hose barb fittings, it’s not enough to know how they work. You also need to know what factors to consider and how to implement professional recommendations.

Design and Installation Tips

Design

The barbs (ridges) on hose barb fittings usually have a cylindrical shape. One end of a hose barb fitting has a barb or ridge that fits securely into the hose, while the other end is made to attach to another part of the system, usually employing a threaded connection.

Installation Tips

- Secure Insertion:To insert the fitting safely and securely into the hose, press the barbed end of the fitting in. The barbs secure the hose by gripping it from the inside.

- Hose Clamp Usage:Use a hose clamp to fasten the hose around the barb for added security. It is essential to avoid a sudden separation, especially under pressure.

- Hose Material:To improve the grip and general security of the fitting within the hose, the small spaces within the barbs are filled with hose substance.

- Hose Removal:To detach a hose from its fitting, cut the tubing far away from the hose barbs with a sharp knife.

Factors While Selecting a Hose Barb Fitting

The following are essential considerations when selecting a hose barb fitting:

- Hose Barb Size:To ensure a secure connection, the outer diameter (OD) of the fitting should be the same as, or only slightly larger than, the hose’s internal diameter (ID).

- Material:The flexibility of the hose’s material determines its size. While hard materials necessitate pinpoint accuracy, flexible materials can accommodate larger barbs. Plastic, stainless steel, aluminum, nylon, brass, etc., are all common materials for fittings.

- Pressure Rating: Checking the hose and fitting’s pressure ratings beforehand to make sure they are suitable for the application’s pressure, especially in high-pressure scenarios.

Applications across Industries

There are many uses for hose barbed fittings, some of which include:

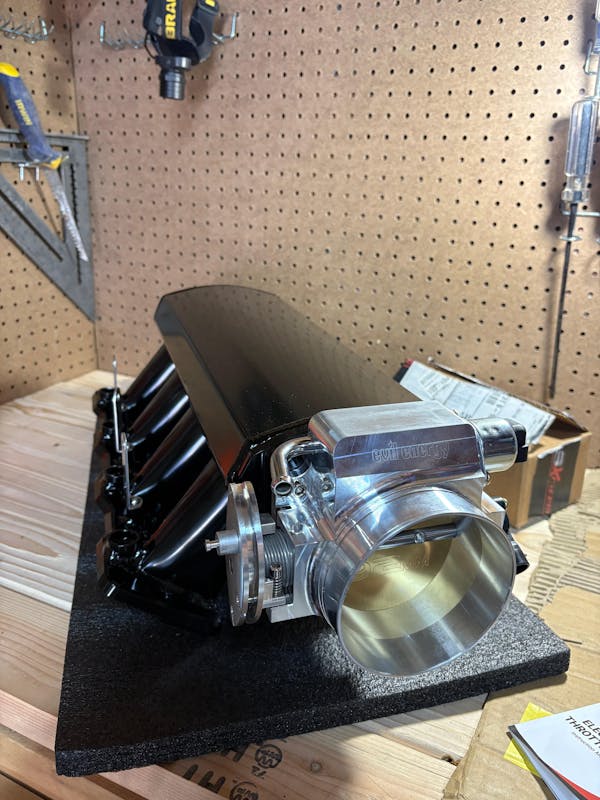

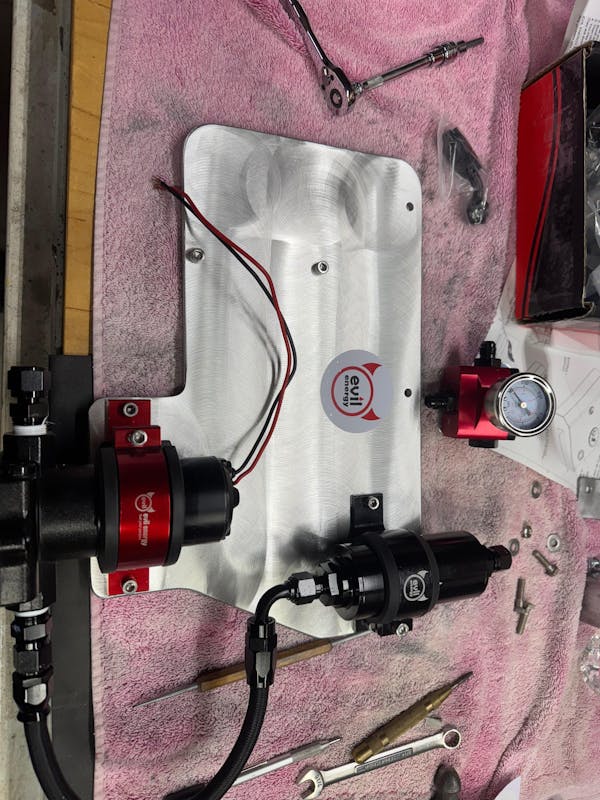

- Automotive Fuel Lines

- Garden Hose Connections

- Laboratory Equipment

- Biopharmaceutical Processes

- Water Treatment Systems

- Pneumatic Systems

- Hydraulic Systems

- Marine Plumbing

- Agricultural Spraying Systems

However, a hose barb fitting is not appropriate for use in high-pressure situations since the pressure could force the barb off the tube. If they are up to the task of withstanding the pressure of the pneumatic or hydraulic system, hose barb fittings can be utilized for it.

Hose Barb Size Chart

Here’s the hose barb size chart that will help in finding the perfect size. The fitting size indicates the external diameter of the hose or device to which the barbed fitting will be attached.

|

Hose Inner Diameter (Inch) |

Hose Inner Diameter (mm) |

Barb Outer Diameter (Inch) |

Barb Outer Diameter (mm) |

Fitting Size (Inch) |

Fitting Size (mm) |

|

1/8 |

3.175 |

1/4 |

6.35 |

1/8 |

3.175 |

|

3/16 |

4.763 |

5/16 |

7.938 |

3/16 |

4.763 |

|

1/4 |

6.35 |

3/8 |

9.525 |

1/4 |

6.35 |

|

5/6 |

7.938 |

7/16 |

11.112 |

5/16 |

7.938 |

|

3/8 |

9.525 |

1/2 |

12.7 |

3/8 |

9.525 |

|

1/2 |

12.7 |

5/8 |

15.875 |

1/2 |

12.7 |

Sizes vary by manufacturer and fitting model. Check the manufacturer’s specs before buying a barbed hose fitting.

Troubleshooting Common Hose Barb Fitting Issues

Hose Barb Fittings are an overlooked component of fluid transfer systems. However, problems might arise with them, just like with any other mechanical part. The most frequently seen issues include leaks, ill-fitting parts, and challenging installations.

- Inaccurate Hose Barb Size

Incorrect hose barb sizing or a sloppy connection are common causes of leaks. Fix this by using hose clamps and checking that the hose and fitting sizes are compatible.

- Improper Fittings

A loose connection or decreased efficiency are both possible outcomes of using the wrong fittings. To keep a system running smoothly, it is necessary to inspect it frequently and choose the right fittings.

Brief Wrap-Up

Hose barbs are a common component of modern fitting and coupling solutions, allowing for the quick and easy connection of a wide variety of tubes and hoses at an affordable price. Identifying the interplay between these factors is crucial to achieving the optimal grip and seal for the system’s needs.

![[20FT] EVIL ENERGY PTFE Fuel Line Kit, complete black hose & fittings set, 180-day return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598065_165x.png?v=1742144807)

![[16FT] EVIL ENERGY PTFE Fuel Line Kit, black braided hose, fittings, free shipping & return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598171_165x.png?v=1742144807)

![CPE Fuel Line[25FT]](http://www.ievilenergy.com/cdn/shop/files/25FTCPE_FuelLine_165x.png?v=1735220649)

![CPE Fuel Line[20FT]](http://www.ievilenergy.com/cdn/shop/files/20FTCPE_FuelLine_165x.png?v=1735220649)