How to Test a Fuel Pump: Troubleshooting Common Symptoms

🎁 A Personal Gift For My Readers

To support your project, I've secured an exclusive 8% OFF for you.

Simply paste the code at checkout.

💡 Use the savings to grab your extra fittings, oil lines, or connectors for free!

Testing a fuel pump is critical for maintaining your vehicle's performance and safety. A malfunctioning fuel pump can lead to stalling, poor acceleration, or even complete engine failure. This guide will walk you through identifying signs of a faulty fuel pump, diagnostic techniques, electrical component testing, and more. Let's dive in!

Understanding Symptoms of a Faulty Fuel Pump

Before diving into tests, it's important to recognize the signs that indicate a faulty fuel pump:

- Difficult Engine Start-ups: If your engine requires several attempts to start, the fuel pump may not be delivering enough fuel.

- Unexpected Stalling: A failing fuel pump can cause your car to stall unexpectedly, especially at stoplights.

- Reduced Acceleration Power: A weak pump may fail under heavy acceleration, causing the vehicle to lack power.

- Abnormal Noises: Unusual whining or whirring noises from the gas tank are often a sign that the fuel pump is nearing the end of its life.

Recognizing these symptoms early can prevent further damage and ensure timely repairs.

Key Diagnostic Techniques for Fuel Pump Issues

When you suspect a fuel pump issue, there are several diagnostic methods you can use to identify the problem:

Visual Inspection and Preliminary Checks

- Step 1: Inspect the fuel pump and surrounding areas for visible damage or leaks.

- Step 2: Check all electrical connections for signs of corrosion or looseness.

Fuel Pressure Testing

Proper fuel pressure is essential for engine performance. Use a fuel pressure gauge to measure the pressure:

- Step 1: Connect the gauge to the system’s test port.

- Step 2: Start the engine and record the pressure reading.

- Step 3: Compare the reading to the manufacturer’s specifications. If it's lower than recommended, the fuel pump may be malfunctioning.

Ensure Electrical Integrity

During the test, ensure there are no electrical issues, such as blown fuses, faulty relays, or corroded wires.

Testing Electrical Components

A fuel pump relies on electrical components for proper function. Here’s how to check them:

Checking Relays, Fuses, and Wiring

- Step 1: Use a digital multimeter to check the voltage at the pump connector.

- Step 2: Inspect wiring, relays, and fuses for any corrosion or damage.

- Step 3: Follow the wiring to ensure there are no breaks or poor connections.

Sound Analysis for Fuel Pump Functionality

Listen for sounds coming from the gas tank. A functioning fuel pump typically emits a quiet hum. A whirring or whining noise is a red flag indicating the pump may be failing.

Utilizing Diagnostic Tools Effectively

Diagnostic tools can help speed up the process of identifying fuel pump issues. Here's how to use an OBD2 scanner:

- Connect the Scanner: Plug the OBD2 scanner into the vehicle’s port (usually under the dashboard).

- Read Error Codes: Review any error codes related to the fuel pump, which will help pinpoint the issue.

- Activate Fuel Circuits: Some scanners allow you to activate the fuel pump circuits, helping you test the pump's performance in real-time.

Using a diagnostic tool streamlines the testing process and provides valuable insights into the condition of your fuel pump.

While you wait for a full repair, there are a few things you can do:

Temporary Fixes

If you're in an emergency, a quick tap on the fuel pump may help temporarily restart the system, especially if there are small blockages. However, remember this is a short-term fix and should not be relied upon for long.

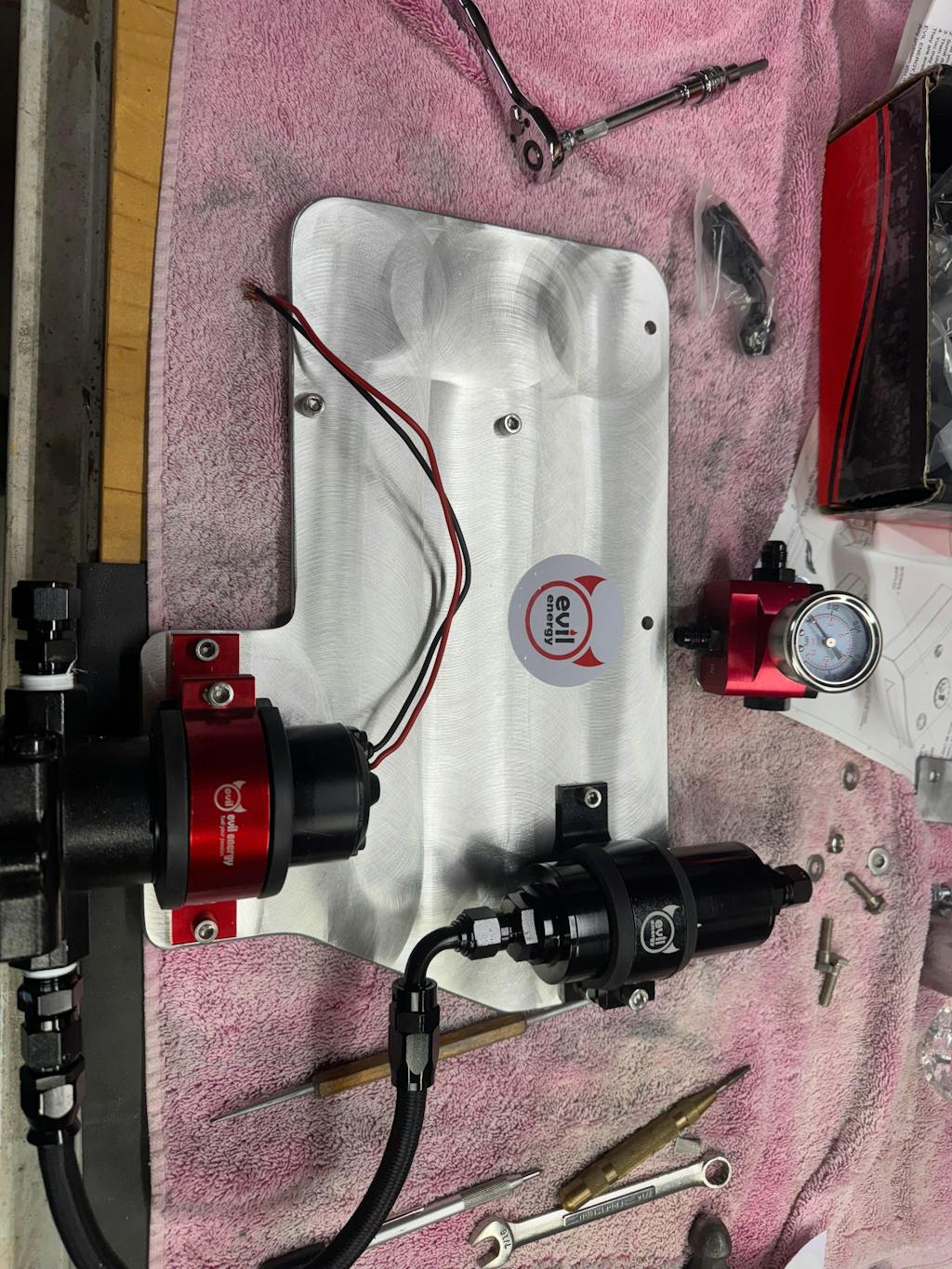

Related reading:HOW DO YOU INSTALL AN EVIL ENERGY FUEL PUMP WITH EXHAUST CLAMPS?

Preventative Maintenance

To avoid future fuel pump issues:

- Use high-quality fuel to reduce the risk of impurities damaging the pump.

- Change fuel filters regularly to keep debris from entering the system.

- Avoid running your vehicle on low fuel levels, as this can strain the fuel pump.

Assessing the Need and Cost of Fuel Pump Replacement

When considering a fuel pump replacement, it's important to evaluate both necessity and cost. The costs associated with replacing a fuel pump can vary significantly depending on the vehicle's make and model. Typically, full replacements range from $400 to $800 for parts and labor. However, if you have basic automotive skills, DIY repairs can drastically cut costs, with parts sometimes as low as $90. While the process isn't excessively complex, it does require some mechanical aptitude, especially considering variations in pump locations, such as under the car or within the gas tank. It is also crucial to address a faulty fuel pump promptly; driving with one can be hazardous, potentially causing your vehicle to stall unexpectedly in traffic. Early replacement not only ensures safety but also maintains the reliability of your vehicle.

Conclusion

Testing and diagnosing fuel pump issues might seem intimidating, but with the right tools and knowledge, it's manageable. Always keep an eye out for common signs of failure, and don't hesitate to use diagnostic tools to confirm the issue. Regular maintenance and timely replacement are key to ensuring your vehicle runs smoothly for years to come.

![[CPE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Fuel-Cell-Tank-Kits-Efficient-Fuel-System-Solutions-5-10-15-Gallon-EVIL-ENERGY-168944374_165x.jpg?v=1772267819)

![[PTFE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-Fuel-Cell-Tank-Kits-Efficient-Fuel-System-Solutions-5-10-15-Gallon-EVIL-ENERGY-168944443_165x.jpg?v=1772267821)

![[PTFE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-LS-Swap-Fuel-Kit-_-Fuel-Filter_6AN-20FT-Fuel-Hose-_20-120PSI-Regulator-_-300LPH-High-Flow-Fuel-Pump-For-LS-Swap-EFI-Systems-and-More-_Copy_-EVIL-ENERGY-139826346_165x.jpg?v=1771519881)

![[CPE]](http://www.ievilenergy.com/cdn/shop/files/EVIL-ENERGY-LS-Swap-Fuel-Kit-_-Fuel-Filter_6AN-20FT-Fuel-Hose-_20-120PSI-Regulator-_-300LPH-High-Flow-Fuel-Pump-For-LS-Swap-EFI-Systems-and-More-_Copy_-EVIL-ENERGY-139826278_165x.jpg?v=1771519878)