Comparing Band Clamp Exhaust and 3-inch V-Band Clamp Solutions

Comparing Band Clamp Exhaust and 3-inch V-Band Clamp Solutions

When piecing together a high-performance exhaust system, selecting the optimal clamps and connectors is crucial for achieving leak-free, durable joints. Two popular options are band-style exhaust clamps and 3-inch diameter v-band couplings. But which one is right for your specific vehicle and application?

In this guide, we’ll do an in-depth comparison of these two exhaust connection styles so you can make an informed decision based on your particular needs and goals. By the end, you’ll know exactly when to reach for band clamps versus v-bands for your exhaust project. Let’s dive in!

1. Clamping Mechanisms

First, a quick overview of how each clamping system operates:

Band Clamp Exhaust Connections

These feature a full 360-degree stainless steel band that sits in a groove on a flanged sleeve piece. Tightening the bolt compresses the sleeve flanges together.

Benefits:

- Broad clamping force distribution

- No leaks between band ends

- Maintains grip when hot

3-Inch V-Band Clamps

These use a v-shaped flanged collar that slides over the joint. The stainless clamp has a V-profile that compresses the flanges when tightened.

Benefits:

- No gaskets required

- Quick connect/disconnect

- Reusable connections

Now, let’s look at relative durability.

2. Strength and Durability

Operating safely under extreme exhaust temperatures and pressures is critical. Here's how the two options compare:

Band Clamp Exhaust Connections

- Maintain constant clamping force. No relaxation over time.

- Heavy-duty designs withstand vibration extremely well.

- Aerospace-grade materials used for race applications.

3-Inch V-Band Clamps

- Also, maintain grip very well long-term.

- Not immune to loosening from vibration.

- More prone to warping or failure if cheap quality is used.

Both create robust connections capable of enduring years of hardcore use when proper materials and design are followed. V-bands are more reliant on precise tolerances and quality.

3. Cost Considerations

You’ll also want to weigh the cost differences when selecting connection types:

3-Inch V-Band Clamps

- Widely available from $20 to $60+ depending on materials used

- Off-the-shelf convenience for standard sizes

Band Clamp Exhaust Connections

- Custom band lengths run $40 to $100+

- Requires custom sleeves sized to the application

V-bands have a cost advantage for one-off applications needing only common sizes. But custom band clamp exhaust kits tailored to your specific headers and piping may provide better fitment and performance.

4. Sealing Capabilities

Preventing exhaust leaks is critical. Here's how the sealing compares:

3-Inch V-Band Clamps

- Deliver gas-tight 360-degree seal when installed correctly

- Minimal leakage risk on straight joints

Band Clamp Exhaust Connections

- Also, provide a leak-free 360-degree seal

- Excellent for junctions needing misalignment compensation

Both v-bands and band clamps produce dependable, leak-tight seals – the most important requirement for any exhaust joint. Band clamps excel in offset mounting situations.

5. Ease of Installation

Installation and assembly speed are another consideration for your project:

3-Inch V-Band Clamps

- Super quick assembly once parts are aligned

- No gasket installation is needed

- Reusable connections

Band Clamp Exhaust Connections

- Require proper sleeve fitment and band sizing

- Gaskets add minor assembly time

- Reusable if disassembled carefully

V-bands win outright for fast swap ability. But band clamp exhaust kits designed specifically for your headers, downpipe, and piping take the guesswork out of fitment.

6. Sizing and Fitment Options

Having size and fitment flexibility is key. Here are the options:

3-Inch V-Band Clamps

- Limited to common v-band sizes, mostly with 3” diameters

- Usually, only one diameter per joint

Band Clamp Exhaust Connections

- Fully customisable band lengths and sleeve diameters

- Multiple sleeves accommodate diameter transitions

Band clamps can be fabricated to match any exhaust layout since sleeve OD and band length are sized specifically to each junction. V-bands offer convenient one-size-fits-all connections if you don't need fully custom joints.

Conclusion

When selecting clamps, consider custom band clamp exhaust connections for race/high-end applications needing precise fitment and robust sealing on complex exhaust headers and pipe routing. Their customisable nature ensures perfect length bands and sleeve diameters.

For simpler exhaust layouts using standard off-the-shelf piping sizes, affordable 3-inch v-band clamps provide reliable performance and quick connect ability. Just source high-quality v-bands designed to withstand racing conditions.

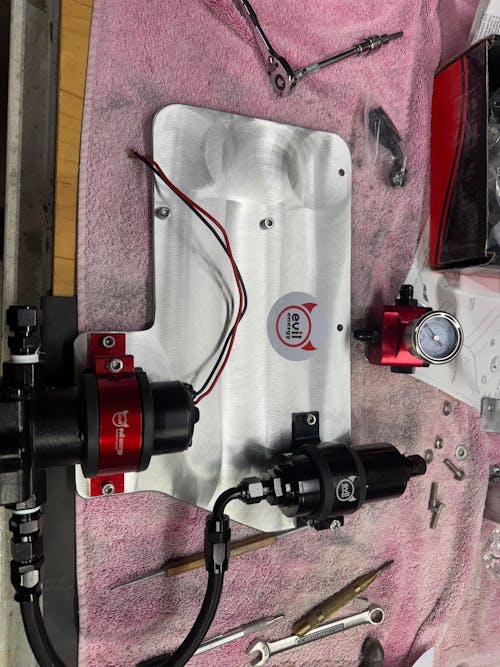

Whatever style you choose, never skimp on clamps guarding your expensive exhaust components from disastrous failures. Always use premium materials from trusted manufacturers like EVIL ENERGY, known for awesome quality production and regular discounted offers. A few dollars saved on clamps is meaningless if it costs you a melted piston!

|

|

3-Inch V-Band Clamps |

Band Clamp Exhaust Connections |

|

Clamp Mechanism |

V-flange collar with tightening band |

Flanged sleeve with a full band |

|

Durability |

Prone to loosening if low-quality used |

Maintains grip exceptionally well, even under rigorous use |

|

Cost |

$20-$60 per clamp available off-the-shelf |

$40-$100+ for custom kits |

|

Sealing Ability |

360-degree seal when installed properly

|

It also seals fully with greater offset tolerance |

|

Installation |

Extremely quick with no gasket installation |

Requires carefully fitting custom sleeves and bands |

|

Size Options |

Usually, just one diameter, like 3" per joint |

Fully customisable diameters and band lengths |

![[20FT] EVIL ENERGY PTFE Fuel Line Kit, complete black hose & fittings set, 180-day return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598065_165x.png?v=1742144807)

![[16FT] EVIL ENERGY PTFE Fuel Line Kit, black braided hose, fittings, free shipping & return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598171_165x.png?v=1742144807)

![CPE Fuel Line[25FT]](http://www.ievilenergy.com/cdn/shop/files/25FTCPE_FuelLine_165x.png?v=1735220649)

![CPE Fuel Line[20FT]](http://www.ievilenergy.com/cdn/shop/files/20FTCPE_FuelLine_165x.png?v=1735220649)