How to Choose the Right Fittings for Your Vehicle

Introduction: Why Fittings Matter in Performance Systems

When building or upgrading a vehicle, one of the most overlooked components is also one of the most critical — fittings. These small connectors play a vital role in every fuel system, oil system, and cooling system, ensuring that fluids move safely and efficiently through your engine bay.

Choosing the wrong fitting doesn't just mean a messy puddle on the garage floor. It can lead to fuel starvation, oil leaks, catastrophic engine failure, or even fire. This is why understanding your system's demands is non-negotiable. Choosing the right fittings ensures performance, reliability, and safety for any automotive or industrial setup.

This guide will walk you through the essential steps to select the perfect fittings for your project, from identifying thread types like AN fittings to understanding when you need specific PTFE fittings.

Understanding the Basics of Fittings

Before we dive into selection, let's cover the most common questions.

What are fittings used for?

Fittings are used to connect, extend, or redirect hoses and tubes in systems that carry fluids or gases. They ensure a secure, leak-free connection between different components, such as a fuel pump fitting connecting to a fuel line, or an oil cooler connecting to the engine block.

What are considered fittings?

Fittings include a wide range of components: connectors, adapters, couplers, elbows (45°, 90°, 180°), tees, and plugs. They are the junctions that join two or more pieces of hose, tube, or pipe together. They can be straight or angled, threaded or quick-connect, depending on the system’s design.

How many types of fittings are there?

There are dozens of types of fittings, classified by their thread type, shape, or material. In automotive performance systems, the most common types you will encounter are AN (Army-Navy) fittings, NPT (National Pipe Tapered), and BSP (British Standard Pipe).

What are the three main types of fittings?

In broad mechanical terms, fittings are often grouped into three main categories:

-

Compression fittings: These seal by compressing a sleeve or ferrule onto a tube.

-

Threaded fittings: These use tapered or straight male and female threads to form a connection.

-

Push-to-connect fittings: These allow for quick, tool-free installation.

Most performance automotive fittings, like AN fittings, are a type of threaded fitting that uses a flared surface for sealing rather than the threads themselves.

Step 1: Understand Your Application

The first rule is to match the fitting to the job. A fitting designed for a low-pressure coolant line will fail catastrophically in a high-pressure fuel system.

Here is a quick-reference table for common automotive applications:

| System | Recommended Fittings | Key Requirements |

|---|---|---|

| Fuel System | AN-6 to AN-8 | High pressure, E85-safe. Must use PTFE fittings for E85. |

| Oil System | AN-8 to AN-10 | High heat and high-pressure resistance. |

| Cooling System | AN-12 to AN-20 | Corrosion resistance, large diameter for high flow. |

| Brake Lines | AN-3 to AN-4 | Extremely high-pressure sealing (often specific inverted flare). |

| Vacuum / Boost | Barb or Push-lock | Easy assembly, positive seal under vacuum or pressure. |

Step 2: Know the Key Thread Types

Mixing thread types is the most common mistake a builder can make. They are not interchangeable and will leak.

| Type | Description | Common Use |

|---|---|---|

| AN (Army-Navy) | 37° flared seal. The 'gold standard' for performance. | Racing, performance fuel systems, oil lines. |

| NPT (National Pipe Taper) | Tapered threads. Requires thread sealant or tape to seal. | Adapters, block fittings, fuel pump outlets. |

| BSP / BSPT | British Standard Pipe. Similar to NPT but with a different thread angle. | Industrial systems, some European/Japanese components. |

| JIC | Industrial 37° flare. Visually similar to AN. | Hydraulic systems. |

Pro Tip: AN and JIC fittings share the same 37° flare angle and are generally compatible in thread pitch and size, though AN fittings are held to a higher standard of specification.

Step 3: Determine the Right Size (AN Sizing)

AN fittings use a standardized sizing system based on the 'dash' number (e.g., -6 AN or AN-6). This number represents the outer diameter (O.D.) of the tubing in 1/16th of an inch.

To find the inner diameter (I.D.) of the corresponding hose, you can use this simple chart.

| AN Size | Hose ID (Approx.) | Common Use |

|---|---|---|

| AN-4 | 1/4-inch | Fuel return lines, small oil lines, brake lines. |

| AN-6 | 3/8-inch | Standard high-performance fuel supply line. |

| AN-8 | 1/2-inch | High-power fuel supply, oil cooler lines. |

| AN-10 | 5/8-inch | Engine oil lines, transmission cooler lines. |

| AN-12 | 3/4-inch | Radiator or coolant lines. |

For example, a common fuel pump fitting setup for a performance build will often use an AN-8 or AN-10 line from the pump to the fuel rail and an AN-6 line for the return.

Step 4: Choose the Right Material

Material choice dictates durability, weight, and chemical compatibility.

| Material | Features | Application |

|---|---|---|

| Aluminum | Lightweight, strong, can be anodized. | Performance builds (fuel, oil, coolant). |

| Stainless Steel | Extremely high strength, superior corrosion resistance. | Brake systems, marine use, high-vibration areas. |

| Brass | Cost-effective, easy to seal, corrosion-resistant. | Low-pressure systems, vacuum lines, some sensor adapters. |

| Nylon / Plastic | Lightweight, affordable, chemical resistant. | Vacuum lines, coolant overflow, push-to-connect systems. |

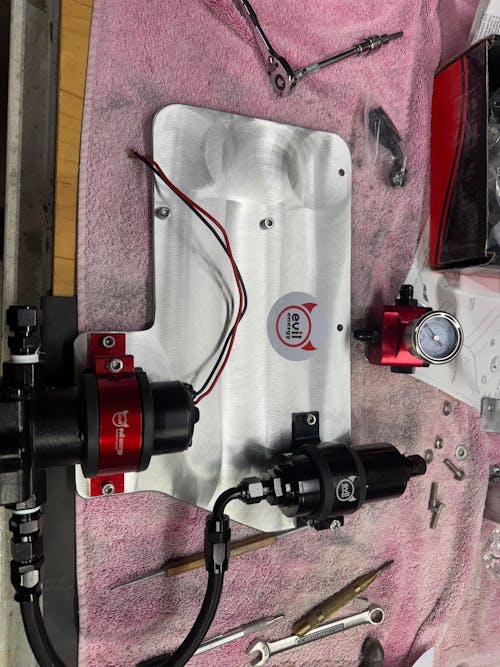

Performance brands like EVIL ENERGY primarily use high-grade 6061-T6 aluminum for their fittings, offering the best balance of strength, weight, and corrosion resistance for demanding applications.

Step 5: Pick the Right Angle and Configuration

Fittings don't just go straight. They come in 45°, 90°, 120°, and 180° angles, as well as T-fittings and Y-blocks. The goal is to create the smoothest possible path for the fluid, with minimal kinks or stress on the hose.

Compact engine bays often require angled fittings to prevent hose kinking or bending. A tight bend in a hose can restrict flow and lead to premature failure.

Step 6: Essential Installation Tips

A perfect fitting can be ruined by a bad installation.

-

Keep it Clean: Ensure the flare and threads are perfectly clean of debris before assembly.

-

Use Sealant (Only on NPT): Only use thread sealant or PTFE tape on tapered threads (NPT). Never use it on AN fittings, as they seal at the 37° flare, not the threads.

-

Don't Overtighten: Overtightening an AN fitting can deform the flare and cause a leak. Snug it up, then give it about a 1/8 to 1/4 turn.

-

Use the Right Tools: Use dedicated aluminum AN fitting wrenches. A standard steel wrench will mar and damage the anodized finish.

Step 7: Common Mistakes to Avoid

-

Mixing Threads: Trying to thread an NPT fitting into a BSP port.

-

Wrong Size: Forcing an AN-8 hose onto an AN-6 fitting.

-

Hose Stress: Installing a hose in a way that puts it in a bind or twists it.

-

Forgetting PTFE: This is a critical one. If you are running E85, methanol, or other corrosive modern fuels, you must use PTFE-lined hoses and compatible PTFE fittings. Standard rubber-lined (CPE) hoses will degrade and fail.

Real-World Feedback from U.S. Users

We've seen what the specs say, but what do builders in the U.S. focus on?

'The hardest part for any first-timer is just knowing which thread type you need—AN, NPT, BSP… It’s a minefield. Once you get that, it’s easy.'

'Color-coded fittings make it so much easier to organize different lines under the hood. I use red/blue for fuel and black for oil. It looks professional and saves headaches.'

U.S. enthusiasts prioritize compatibility, a leak-proof seal, ease of installation, and aesthetics. This is why the anodized finish on EVIL ENERGY fittings is so popular; it provides both corrosion protection and the clean, organized look that builders demand.

Conclusion: Get the Right Connection

Choosing the right fitting comes down to five key factors: your application, thread type, size, material, and angle. By carefully matching these five elements, you create a plumbing system that is not only reliable and safe but also capable of supporting your vehicle's performance goals.

Ready to build your system with confidence? EVIL ENERGY offers a complete line of high-performance AN fittings, adapters, PTFE fittings, and hoses engineered for performance and durability—trusted by enthusiasts and professionals worldwide.

![[20FT] EVIL ENERGY PTFE Fuel Line Kit, complete black hose & fittings set, 180-day return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598065_165x.png?v=1742144807)

![[16FT] EVIL ENERGY PTFE Fuel Line Kit, black braided hose, fittings, free shipping & return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598171_165x.png?v=1742144807)

![CPE Fuel Line[25FT]](http://www.ievilenergy.com/cdn/shop/files/25FTCPE_FuelLine_165x.png?v=1735220649)

![CPE Fuel Line[20FT]](http://www.ievilenergy.com/cdn/shop/files/20FTCPE_FuelLine_165x.png?v=1735220649)