Fuel Cell Gas Tank Guide: Everything You Need to Know from Basics to Upgrades

🎁 A Personal Gift For My Readers

To support your project, I've secured an exclusive 8% OFF for you.

Simply paste the code at checkout.

💡 Use the savings to grab your extra fittings, oil lines, or connectors for free!

What Is a Fuel Cell?

Fuel cells are specialized fuel storage units often used in motorsports, off-road racing, and performance builds. While the term 'fuel cell' may remind people of hydrogen fuel cells used for energy conversion, in the context of automotive use, it refers to racing-grade gas tanks that are engineered for safety, durability, and fuel management.

📌 Note: A fuel cell, as defined on Wikipedia, refers to a device that converts chemical potential energy (from fuel) into electricity. However, in the performance automotive world, a fuel cell gas tank is a different concept—it’s a safety-focused container for storing liquid fuel like gasoline or ethanol.

A fuel cell gas tank is a special type of fuel tank built for racing, off-road driving, and high-performance vehicles. Unlike the stock gas tanks found in daily drivers, fuel cells are made to handle tough conditions, focusing on safety, consistent fuel flow, and strong structural protection.

Why Do Racers Use Fuel Cell Gas Tank

What really sets a fuel cell apart is its tough, reinforced design. It usually includes welded metal walls, foam inside the tank to prevent fuel from sloshing, and tight-sealing AN fittings. These features help prevent leaks, reduce vapor buildup, and even lower the risk of fire or explosion in a crash.

That’s why fuel cells are a top choice for builds that push limits—like drift cars, track vehicles, off-road rigs, and engine swaps. In these cases, stock tanks just aren’t built to keep up with the power, pressure, or punishment of serious performance use.

📌 Note: In this context, both 'fuel cell' and 'fuel cell gas tank' refer to the same thing.

What is included in a Fuel Cell Gas Tank?

A high-quality electric fuel cell gas tank includes:

-

Welded aluminum or steel shell – Provides structural rigidity and resists impact

-

Explosion-resistant foam – Stabilizes fuel and reduces risk of vapor ignition

-

Anti-slosh foam instead of internal baffles – Controls fuel movement and maintains stability during acceleration, cornering, or impact, enhancing overall safety

-

AN fittings(e.g., -6AN, -8AN, -10AN) – Secure, leak-resistant threaded connections for fuel feed and return lines

-

Fuel level sender – Lets you monitor fuel levels from your dash

-

Rollover valves & vented caps – Maintain internal pressure and seal during vehicle flips or impacts

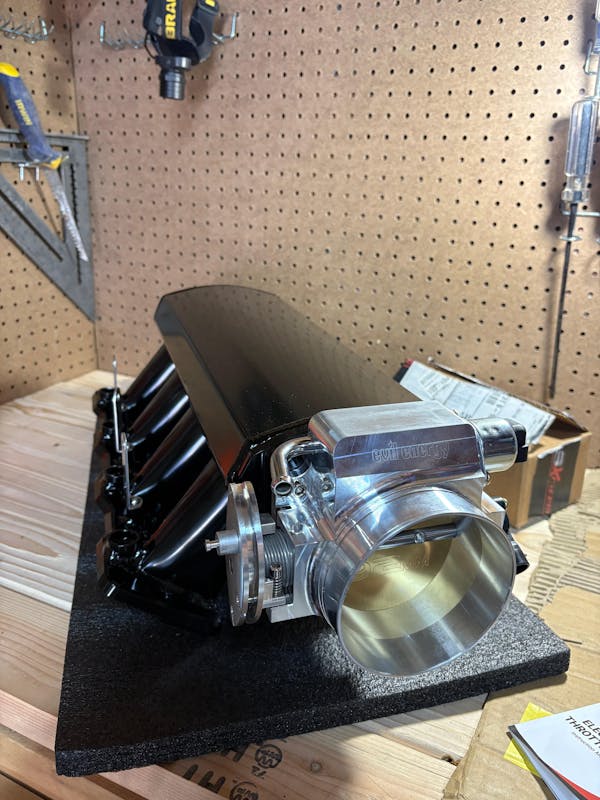

Product Case Study: EVIL ENERGY Fuel Cell

As an example, EVIL ENERGY offers aluminum alloy fuel cell gas tanks in various capacities, such as 5, 10, and 15 gallons, designed for robustness and a good seal.

- Level Sensing: The EVIL ENERGY Fuel Cells come with a built-in 0 to 90 ohms sensor for continuous monitoring of the fuel level in the tank.

- Safety & Stability: The gasoline fuel cell cover is equipped with anti-sway foam inside, which is crucial for maintaining a consistent fuel supply and helps prevent vapor from exploding from the empty part of the tank.

- Material: The fuel tanks are constructed from aluminum alloy.

Each of these elements works together to support a reliable, sealed, and responsive high-performance fuel system.

Where Are Fuel Cells Used Today?

Fuel cells are widely used in:

-

Track and circuit builds, where consistent fuel delivery is critical at high speeds and G-forces

-

Drift cars, which demand compact tanks with superior slosh resistance

-

Off-road vehicles, where fuel must remain stable over angled terrain and vibration

-

LS swaps and engine conversions, where trunk-mounted or rear fuel cells allow better space usage and routing flexibility

When to Use a Fuel Cell vs. an OEM Gas Tank

| Use Case | Recommended Option | Reasoning |

|---|---|---|

| Daily commuting | OEM Fuel Tank | Emissions compliant, higher capacity, no modification needed |

| Weekend driving / Autocross | Small Fuel Cell Gas Tank | Lightweight, compact layout, reduces fuel slosh |

| Drifting / Track use / High G | Gasoline Fuel Cell | Internal foam stabilizes fuel, delivers consistent flow |

| Off-road or high-vibration use | Gasoline Fuel Cell | Reinforced structure, better shock and corrosion resistance |

| Engine swaps / LS conversions | Gasoline Fuel Cell | Custom port options, external pump support, flexible routing |

| Regions with emissions testing | OEM Fuel Tank | Easier to stay street legal with factory systems |

| Budget builds / No chassis mods | OEM Fuel Tank | Lower cost, no need for custom mounting or plumbing |

Fuel Cell vs OEM Gas Tank – Which One Do You Need?

Formed Tank vs. Custom Cell

When comparing a fuel cell gas tank to a traditional molded gas tank, the most significant difference lies in the internal structure and how each tank is built.

-

Welded vs. Molded Construction

-

Most factory gas tanks are rotationally molded plastic shells—lightweight and affordable for mass production, but offering limited strength and no internal support.

-

In contrast, a fuel cell is TIG-welded from aluminum or steel, with reinforced seams and corners, creating a strong, crash-resistant shell ideal for racing, drifting, or custom installs.

| Type | Structure | Strength |

|---|---|---|

| OEM Gas Tank | Hollow molded plastic | Flexible, lower impact resistance |

| Fuel Cell | TIG-welded aluminum or steel plates | Rigid, highly impact-resistant |

-

Hollow Cavity vs. Foam-Filled Design

-

OEM tanks are empty inside. During hard cornering or braking, fuel sloshes, causing pressure spikes and increasing the risk of fuel vapor ignition.

-

Fuel cells are foam-filled with explosion-resistant baffle material. This foam controls fuel motion, absorbs impact energy, and helps suppress combustion if a crash occurs.

| Type | Interior Design | Fuel Control |

|---|---|---|

| OEM Gas Tank | Empty cavity | High fuel movement |

| Fuel Cell | Foam-filled interior | Stable fuel delivery, shock absorption |

Material Comparison – Aluminum, Steel, Composite

Fuel cells are typically constructed from aluminum or steel:

-

Aluminum: Lightweight, corrosion-resistant, and ideal for track or drift builds. Often used with 2mm+ thick walls and anodized coatings for extra durability.

-

Steel: Heavier but extremely strong, suitable for off-road applications with higher puncture resistance.

-

Composites: Rare but used in specialized racing environments for extreme weight savings.

Compared to plastic OEM tanks, fuel cells offer significantly higher tensile strength, rigid mounting, and better heat resistance.

Leak Prevention & Crash Protection

Fuel cells are purpose-built to eliminate weak points that can lead to leaks, ruptures, or fires—especially during collisions.

-

Leak-Proof Structural Design

-

AN fittings: Threaded, aerospace-grade connections that hold tight under high fuel pressure.

-

Fully welded shell: TIG welding eliminates seams or rivets that might corrode or fail.

-

Roll-over vent valve: Seals manually with a secure cap to prevent spills or vapor release during use.

-

Explosion-Resistant Internal Foam

-

Anti-slosh foam fills the tank’s cavity, absorbing shock and reducing fuel vapor buildup.

-

Foam is non-flammable, fuel-safe, and heat-resistant.

-

It keeps fuel pressure stable during hard acceleration, cornering, or uneven terrain.

-

Durable, High-Grade Materials

-

Aluminum offers excellent strength-to-weight ratio and impact durability.

-

Wall thickness ≥2mm helps resist puncture, especially in off-road or track scenarios.

-

Many fuel cells are anodized or coated to protect against corrosion in humid or dirty environments.

-

Integrated Safety Components

-

Fuel filters and pressure regulators

-

External or in-tank pumps, offering flexibility based on build type

-

Secure fuel lines to prevent leakage or heat damage

A modern fuel cell gas tank combines reinforced welded construction, internal foam baffling, and sealed AN fittings to create a fuel system that’s leak-proof, explosion-resistant, and purpose-built for performance driving. Compared to traditional plastic tanks, it offers a far safer and more durable solution—especially for high-horsepower builds or track applications.

Fuel Cell vs. OEM Gas Tank – What’s the Difference?

OEM fuel tanks are made for daily driving—not racing or rugged terrain. Most lack features like:

-

Surge protection

-

Anti-slosh foam

-

Reinforced outlets or high-flow fittings

Fuel cells, on the other hand, are purpose-built for demanding use:

-

Compact TIG-welded shells fit tight spaces (trunks, rear seat deletes, truck beds)

-

Internal foam reduces fuel movement and vapor buildup

-

AN fittings enable secure, leak-resistant fuel routing

-

Stronger aluminum or steel construction resists rupture

Bottom line: For custom builds, swaps, or racing, a fuel cell offers better safety, flow stability, and modularity.

Controlling Fuel Slosh for Performance and Safety

Hard launches, sharp turns, or steep climbs can cause fuel to slosh violently inside a tank. This leads to:

-

Fuel starvation

-

Vapor lock

-

Pressure spikes

-

Even system failure under high G-forces

Fuel cells solve this by including:

-

Anti-slosh foam that disperses wave motion

-

Crash-resistant design that maintains structural integrity

This ensures reliable fuel delivery under any driving condition.

How a Fuel Cell Gas Tank Works in High-Performance Builds

In a performance fuel system, each component plays a role in clean, pressurized delivery:

Step-by-step layout:

-

Fuel exits the cell through a large feed port (usually -10AN).

-

Passes through a 100-micron pre-filter to catch large debris.

-

Enters an inline fuel pump for pressurization (ideal for EFI).

-

Flows into a 10-micron post-filter for fine particle filtration.

-

Reaches the fuel pressure regulator, which ensures steady PSI.

-

Excess fuel returns to the tank in a loop, preventing vapor lock and pressure spikes.

Tip: Always mount the fuel pump below the feed outlet. This helps gravity prime the pump, reducing cavitation and wear.

Can a Fuel Cell Be Used for Gasoline or E85?

Yes, you can use E85 – with the Right Setup

Gasoline Safe? – Lining and Bladder Options

Yes—but only if the fuel cell is designed for it. Look for:

-

Internal bladders or fuel-safe coatings to prevent corrosion

-

Ethanol-compatible foam that won’t degrade over time

-

Sealed AN fittings and non-rubber gaskets to resist fuel vapor breakdown

Standard aluminum or steel cells without proper linings can corrode or leak over time when used with pump gas.

Using E85, Ethanol, or Methanol – What You Must Know

E85 and alcohol-based fuels are more aggressive than gasoline. They:

-

Absorb water, which accelerates corrosion

-

Break down traditional fuel foam and seals

-

Require non-reactive linings like Teflon, plastic bladders, or hard anodized coatings

📌 Tip: Choose E85-compatible fuel cells with marked ethanol-safe components if your build runs flex-fuel or full alcohol blends.

Corrosion Resistance – Foam & Coating Checklist

For any fuel type, check if your fuel cell uses:

-

Closed-cell anti-slosh foam, safe for ethanol/methanol

-

Anodized or polymer-coated aluminum walls

-

Stainless or PTFE internal fittings

-

Bladder-style liners for high-end resistance

Failing to match fuel type with proper internal materials can lead to fuel system failure or safety hazards.

The EVIL ENERGY Fuel Cell Gas Tank is fully compatible with gasoline,E85—just make sure to choose PTFE (Teflon-lined) fuel lines when setting up your system for safe and long-lasting performance.

Best Practices for Safe Gasoline or E85 Use

Venting & Pressure Regulation

-

Pressure buildup

-

Vapor lock

-

Fume accumulation Use rollover vent valves and pressure regulators designed for your fuel type.

Seals, Valves, and Vapor Control

-

Use ethanol-rated check valves and O-rings

-

Install vapor barriers in trunk-mounted setups

-

Maintain proper return lines to relieve system pressure

Fire Prevention Tips for Fuel Cell Installs

-

Never mount near heat sources (exhaust, turbo piping)

-

Always secure the cell to avoid movement or puncture

-

Use braided fuel lines with thermal sleeves where needed

What Fuel Pump Should You Use with a Fuel Cell?

Choosing the right fuel pump is essential for getting consistent performance from your fuel cell. Whether you're building an EFI swap, a high-horsepower drag car, or a reliable off-road rig, your pump setup must match your flow needs, mounting layout, and fuel type.

In-Tank vs. Inline Fuel Pump Systems

When to Choose External Inline Pumps

Inline fuel pumps are mounted outside the tank, typically below the fuel cell’s feed outlet. They’re easy to inspect, replace, and upgrade—ideal for:

-

Custom builds with limited in-tank space

-

Trunk-mounted fuel cells

-

EFI conversions needing high-volume flow

-

Swaps where the pump must be relocated (e.g. LS swaps)

Inline pumps are also preferred when you're running:

-

Return-style systems

-

Dual filters and pressure regulators

-

External surge tanks or filters

In-Tank Advantages – Cooling and Noise Reduction

In-tank fuel pumps are immersed in fuel, which provides:

-

Natural cooling, helping extend pump life

-

Quieter operation, since the tank dampens pump sound

They're often used in OEM-style applications, and can be integrated with aftermarket fuel cells that support internal pump modules or surge tanks. However, they are harder to service and upgrade.

Why Inline Pumps Are More Common in Race and Swap Builds

Inline pumps dominate in high-performance builds because they:

-

Offer higher flow rates at high pressure

-

Can be mounted in accessible locations

-

Work well with modular fuel systems (surge tanks, filters, regulators)

-

Make tuning and diagnostics easier

For most fuel cell-based builds, especially EFI or boosted setups, an external inline pump is the more flexible and race-proven option.

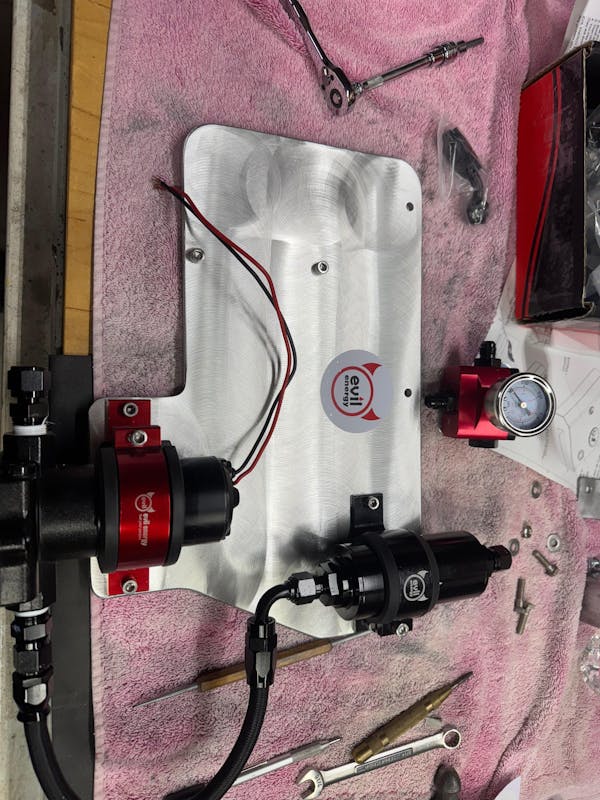

Regulator & Filter Pairing Tips

For best performance and fuel system protection, especially in high-output or boosted builds, follow this recommended setup:

-

100-micron pre-filter (higher rating) – Installed before the fuel pump, it catches larger particles to protect the pump from debris.

-

10-micron post-filter (finer filtration) – Installed after the pump, this filter captures finer contaminants before fuel reaches the injectors or carburetor.

-

Return-style fuel pressure regulator with vacuum/boost reference – Ensures stable fuel pressure under varying load, especially important for turbo or supercharged applications

This ensures clean, consistent, and tunable pressure delivery to your injectors or carburetor.

Recommended Pump + Fuel Cell Kit Pairings

EVIL ENERGY offers several combo kits designed for specific setups:

Should You Upgrade to a Fuel Cell? Here’s the Bottom Line

Fuel cells aren’t for everyone—but if you’re building for performance, safety, or layout flexibility, they may be the right move. Here’s how to decide:

A Fuel Cell Is Worth It If You...

You run high-horsepower, boosted, or track-only builds

If your vehicle makes over 500+ HP, uses turbocharging or supercharging, or sees regular track time, a stock gas tank likely won’t keep up. A fuel cell offers better fuel stability, flow control, and fire resistance.

You need custom fuel routing or trunk relocation

Building an LS swap? Running dual pumps? Mounting your tank in the trunk or bed? Fuel cells make it easier to route AN lines, add external components, and optimize space.

You want maximum safety under extreme conditions

With welded construction, anti-slosh foam, and leak-proof fittings, fuel cells dramatically reduce the risk of vapor lock, leaks, or explosion during crashes or high-load operation.

🚫 A Fuel Cell May Not Be Ideal If You...

❌ Drive daily on public roads without emissions certification

Most fuel cells lack EVAP fittings, charcoal canister support, or DOT approval. They’re not street-legal in some areas, especially where emissions testing is required.

❌ Prefer plug-and-play simplicity

Fuel cells often require custom mounting, AN fuel line routing, and electrical wiring. If you’re looking for a bolt-on upgrade, this system may be too complex.

❌ Don’t have space, tools, or time for custom install

Fuel cells typically need cutting, fabrication, or reworking the spare tire well. Without the right tools or workspace, installation can become a barrier.

📌 Tip:

If your build demands reliability, safety, and fuel system precision, and you’re ready for some hands-on work, a fuel cell is one of the smartest upgrades you can make to your high-performance vehicle.

Explore EVIL ENERGY Fuel Cell Kits

Fuel Cell Gas Tank Kits – Multiple Capacities Available

-

Capacities: 8 / 10 / 15 / 17 / 19 gallons

-

Fitment: Varies by model – compact, mid-size, and V8 RWD platforms

-

Recommended for: Universal swap builds, 240SX, Mustang, classic Civics, and other tuner platforms

10-Gallon Fuel Cell Kit

-

Compact size for tight installs

-

Ideal for drift cars, lightweight track builds, or rear seat delete conversions

19-Gallon Fuel Cell Kit with Level Sender

-

Large capacity suitable for street cars and high-displacement platforms

-

Includes integrated fuel level sender

❓FAQs

Q1: What is a fuel cell, and how does it work?

A fuel cell is a high-performance fuel tank designed for racing, off-road, or modified vehicles. It uses internal foam and AN fittings to safely store and deliver fuel under high load and pressure.

Q2: What is the difference between a fuel cell and a fuel cell gas tank?

In motorsports, the terms are often interchangeable. Unlike OEM gas tanks, fuel cells use stronger materials, internal baffling, and modular fittings for better safety and customization.

Q3: Are fuel cells safer than OEM gas tanks?

Yes. Fuel cells are built with anti-slosh foam, rollover safety valves, and fully welded aluminum shells, offering superior impact resistance and vapor control in racing conditions.

Q4: What are AN fittings and why are they important in a fuel cell system?

AN fittings are aerospace-grade, threaded fuel line connectors. They create leak-proof, high-pressure seals—essential for fuel delivery in performance or boosted applications.

Q5: What is fuel slosh, and how do fuel cells prevent it?

Fuel slosh is the violent movement of liquid fuel during hard braking or cornering. Fuel cells use foam and internal baffles to stabilize fuel flow and reduce the risk of starvation or pressure loss.

Q6: Can a fuel cell be used for gasoline or E85?

Yes, most performance-grade fuel cells—including those from EVIL ENERGY—can safely store gasoline, E85, ethanol, or methanol, as long as the right materials are used throughout the system.

To ensure long-term reliability and fuel compatibility:

-

Use PTFE-lined fuel hoses (Teflon) to prevent swelling or degradation from ethanol.

-

Verify that all fittings, seals, and foam inside the fuel cell are E85-rated.

-

Avoid using standard rubber hoses, which can break down when exposed to ethanol-based fuels.

Tip: EVIL ENERGY Fuel Cell Tanks are E85-compatible, but you must pair them with PTFE fuel lines and E85-safe fittings for optimal performance and safety.

Q7: Do fuel cells come with fuel pumps or do I need to buy one separately?

Most fuel cells are sold without pumps. You’ll need to add an inline or in-tank fuel pump, along with filters and regulators, based on your engine’s fuel requirements.

Q8: How do I choose the right size fuel cell for my car?

-

8–10 gallons: Compact builds, drift cars, race-only setups

-

15–19 gallons: Street cars, turbo builds, long-distance performance use Match your horsepower, available space, and fuel type when selecting.

Q9: Is it legal to use a fuel cell on the street?

Not always. Most fuel cells are not DOT-certified and may lack emissions equipment like EVAP ports or level sensors. Always check your local laws before installation.

Q10: What tools and accessories do I need to install a fuel cell gas tank?

Basic installation typically requires:

-

AN fuel lines and fittings

-

Fuel filters and pressure regulator

-

Mounting brackets or straps

-

Wrenches, hose clamps, drill, and sealant

![[20FT] EVIL ENERGY PTFE Fuel Line Kit, complete black hose & fittings set, 180-day return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598065_165x.png?v=1742144807)

![[16FT] EVIL ENERGY PTFE Fuel Line Kit, black braided hose, fittings, free shipping & return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598171_165x.png?v=1742144807)

![CPE Fuel Line[25FT]](http://www.ievilenergy.com/cdn/shop/files/25FTCPE_FuelLine_165x.png?v=1735220649)

![CPE Fuel Line[20FT]](http://www.ievilenergy.com/cdn/shop/files/20FTCPE_FuelLine_165x.png?v=1735220649)

1 comment

product quality, and price