How Does a Water Pump for Car Work in the Cooling System?

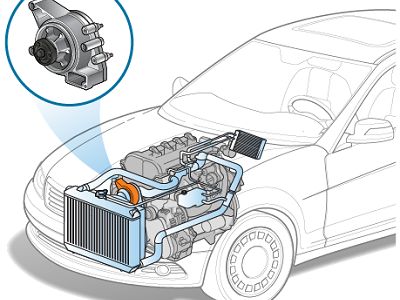

The water pump for car is a crucial component of a vehicle's cooling system. Located at the front of the car engine, it keeps the coolant circulating to maintain the engine's optimal operating temperature. The term 'water pump' is commonly used but the correct term is 'coolant pump.' This is because it circulates a mixture of 50% water and 50% coolant which varies depending on the climate.

What is a Water Pump for Car and How Does It Work?

The water pump for car is responsible for circulating coolant throughout the engine to keep it from overheating. The pump is powered by a belt connected to the crankshaft, and it operates continuously when the engine is running, ensuring even temperature distribution within the engine. A malfunctioning water pump can lead to severe engine damage, making it vital to maintain this critical part of your vehicle.

Why Do We Need a Cooling System?

The ideal operating temperature for an engine is approximately 200°F (90°C). At this temperature:

- Oil flows smoothly, ensuring proper lubrication.

- Combustion in the cylinder is efficient.

However, when the engine is running, temperatures can rise much higher than this. To prevent engine components near the combustion process from overheating, a cooling system is essential. Most cooling systems share a similar structure and function, making them a universal feature across various vehicles.

How Does Coolant Work?

Coolant, a mixture of water and ethylene glycol, plays a vital role in transferring heat from the engine to the radiator. Here's how it works:

- Heat Transfer: Coolant absorbs heat from the engine's hottest parts.

- Radiator Cooling: The heated coolant travels to the radiator, where airflow cools it down.

When the engine reaches its operating temperature, the water pump for car pulls cold coolant from the bottom of the radiator and circulates it around the engine. The coolant then moves:

- Around the cylinder.

- Up into the cylinder head, cooling the valves.

- Out to the radiator to release heat.

How Does a Water Pump Work?

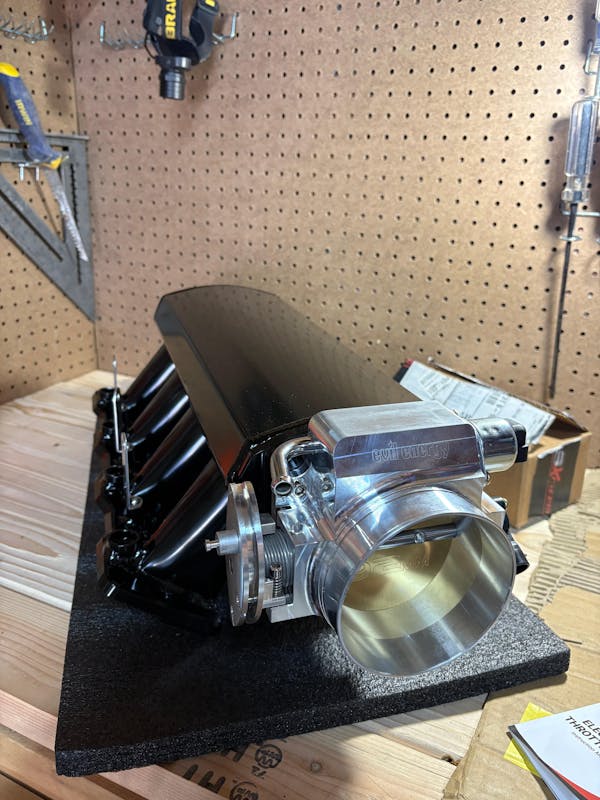

The mechanical water pump consists of several key parts, including:

- Housing: Typically made of cast aluminum.

- Impeller: Spins the coolant to maintain circulation.

- Bearing Assembly: Supports the pump shaft and ensures smooth operation.

- Seal: Prevents coolant leaks.

The water pump for car is powered by a belt connected to the crankshaft. Depending on the vehicle, it may be driven by the timing belt, camshaft, or directly off the crankshaft. Regardless of how it's powered, the pump operates continuously when the engine is running, ensuring even heating within the engine.

Parts of a Water Pump for Car

A water pump for car includes the following components:

- Shaft and Pulley: Connected to the crankshaft via a belt to drive the pump.

- Impeller: Sits inside the engine and spins coolant outward, creating pressure.

- Volute: A spiral-shaped housing around the impeller that ensures efficient coolant flow.

When to Replace a Water Pump for Car

Water pumps for cars are typically replaced as a unit and are often changed during timing belt replacement to save on labor costs. Here are signs that your water pump for car needs replacement:

- Coolant Leaks: Check for crystallized coolant around the weep hole or dripping coolant.

- Unusual Noises: A growling noise may indicate bearing issues.

- Overheating Engine: This could signal impeller failure.

Common Water Pump Failures in Cars

A water pump for car can fail in three main ways:

-

Seal Failure:

This is usually caused by bearing failure, which puts extra strain on the seal. The solution is to replace the entire water pump. -

Bearing Failure:

Bearings can wear out, making the pump noisy or difficult to turn. You can test this by turning the pulley manually. If it's hard to turn or makes noise, replace the pump. -

Impeller Damage:

Impellers can corrode or break, especially if they're made of plastic. A damaged impeller can cause engine overheating. Check by squeezing the top radiator hose while the engine is running. If there's no coolant movement, the impeller may need replacing.

How to Identify a Leaking Water Pump for Car

The weep hole on a water pump for car allows small amounts of coolant to escape, which is normal. However, if there is excessive coolant leakage or crystallization, it may indicate a damaged seal or bearing. It’s important to check for leaks regularly to prevent serious engine damage.

Modern Water Pumps for Cars: Efficiency at Its Best

Modern water pumps for cars are incredibly efficient. A standard pump can circulate coolant through the engine up to 20 times per minute at high speeds. This ensures consistent engine cooling and optimal performance.

By maintaining your water pump for car and cooling system, you can prevent overheating, extend engine life, and ensure your vehicle runs smoothly. If you notice any of the symptoms mentioned above, consult a mechanic promptly to avoid costly repairs.

![[20FT] EVIL ENERGY PTFE Fuel Line Kit, complete black hose & fittings set, 180-day return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598065_165x.png?v=1742144807)

![[16FT] EVIL ENERGY PTFE Fuel Line Kit, black braided hose, fittings, free shipping & return](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598171_165x.png?v=1742144807)

![CPE Fuel Line[25FT]](http://www.ievilenergy.com/cdn/shop/files/25FTCPE_FuelLine_165x.png?v=1735220649)

![CPE Fuel Line[20FT]](http://www.ievilenergy.com/cdn/shop/files/20FTCPE_FuelLine_165x.png?v=1735220649)