Complete Guide to Hoses & Fittings: Types, Functions, and How to Choose

When modifying or repairing a vehicle, hoses (lines) and fittings are essential components you simply can't overlook. Whether you're working on the fuel system, cooling system, or vacuum lines, choosing the right type of hose and matching fittings directly affects your build’s sealing performance, safety, and long-term durability.

This guide will walk you through the different types of hoses and fittings, explaining their key differences, functions, and best-use scenarios—perfect for both DIY enthusiasts and professional mechanics.

What Are Hoses and Fittings?

When working on a car—especially when upgrading or replacing fuel systems, cooling setups, or oil routing—you'll often hear about hoses and fittings. But what exactly are they, and why are they so important?

Basic Overview of Hose & Line Systems

A hose (or fuel line) is a flexible tube that carries fluid—like fuel, coolant, or oil—from one part of your vehicle to another. Think of it as the 'veins' of your car. Just like blood needs to move through your body, fuel and other fluids need to move through your car safely and efficiently.

Hoses come in different materials depending on what they’re carrying:

-

Some are built for high temperatures (like those near the engine)

-

Others are made for high pressure (like in fuel-injection systems)

-

Some are resistant to chemicals like ethanol or diesel

What Are Fittings and Why Are They Important?

Fittings are the connectors that join hoses to other parts—like fuel pumps, filters, radiators, or engines. They make sure the hose stays in place and doesn’t leak. Without the right fitting, even the best hose won’t work properly.

There are many types of fittings:

-

AN fittings are common in performance and racing applications

-

Quick-disconnect fittings are often used in EFI (Electronic Fuel Injection) setups

-

Push-lock fittings are easy to install and great for low-pressure systems

Each fitting must match the hose size, material, and function—otherwise you risk leaks, fuel pressure drops, or even system failure.

Role of Hoses & Fittings in Fuel, Cooling, and Oil Systems

-

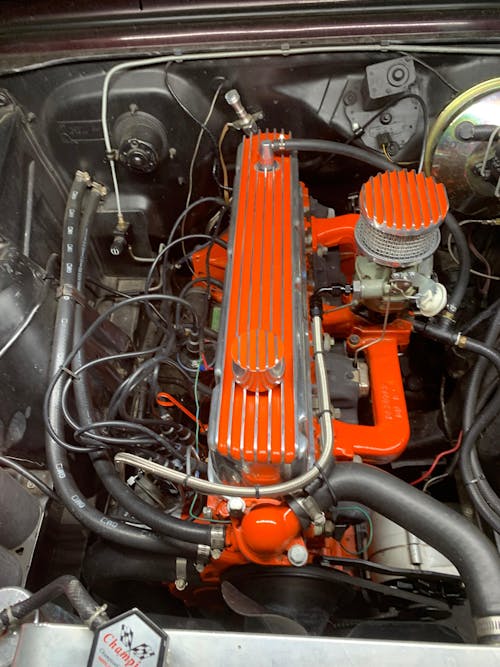

Fuel System: They deliver gasoline or diesel from the tank to the engine. High-performance setups (like turbocharged or EFI engines) require stronger hoses and precise fittings to handle pressure and prevent leaks.

-

Cooling System: These hoses move coolant between the engine and the radiator. If a hose fails, the engine could overheat.

-

Oil System In performance cars, oil might be routed through external coolers or catch cans—relying on strong hoses and fittings to keep everything sealed under high heat.

Common Types of Fuel Lines & Hoses

Choosing the right fuel line is essential to building a reliable and safe fuel system. Whether you’re upgrading a street car, tuning a race build, or outfitting a marine engine, each type of fuel hose is made for a specific use case.

Here, we break down each fuel hose type in detail—so whether you’re building a high-performance street car or a marine engine, you’ll know what to use and why.

PTFE Fuel Lines

Features, Materials, and Use Cases (High temp, ethanol-safe)

PTFE (Polytetrafluoroethylene) fuel lines are the top choice for high-performance and high-temperature fuel systems. Known for their superior chemical resistance and ability to handle modern fuels like E85, methanol, and diesel, PTFE lines are durable, non-permeable, and long-lasting.

Material Composition:

-

Inner layer: PTFE (polytetrafluoroethylene)

-

Middle layer: Stainless steel core

-

Outer layer: Stainless steel braid (silver finish), optionally with an outer black nylon sleeve for abrasion resistance

-

Must use PTFE-specific fittings only

-

Transmission fluid, coolant, oils, pump gases, racing gases, vacuum, hydraulic oil, diesel, regular fuel, and E85 gasoline

-

High-performance, turbocharged, fuel-injected engines, E85 conversions

-

High temperature rating (up to 500°F / 260°C)

-

Rigid hose; avoid sharp bends or folds

-

Provides superior chemical resistance and long-term durability

Running E85 on a turbocharged LS swap? A PTFE fuel line with stainless steel or nylon braided outer layer will ensure long-term performance without fuel seepage or vapor loss.

CPE Fuel Lines

Cost-effective braided hose for general fuel use

CPE (Chlorinated Polyethylene) braided hoses offer a balance between performance and affordability. Featuring a synthetic rubber core and a braided stainless steel or nylon outer layer, these lines are flexible, easy to route, and suitable for most common fuels.

-

Material Composition: Inner layer of CPE rubber, stainless steel core in the middle, and an outer layer of either black nylon braid or stainless steel braid.

-

Compatible Fittings: Designed to work with swivel (rotary) fittings and push-in fittings only.

-

Compatible Fluids: Suitable for transmission fluid, coolant, oils, pump gases, racing gases, vacuum, hydraulic oil, diesel, and regular fuel.

-

Limitations: Best not used with E85 gasoline, as it can reduce the hose’s lifespan.

Swapping in a fuel-injection system on your classic Mustang? A CPE braided fuel hose is a solid choice—easy to work with and built to last.

NBR Fuel Hoses

Budget-friendly option for low-pressure systems

NBR (Nitrile Butadiene Rubber) hoses are ideal for low-pressure fuel systems, especially older carbureted engines and small power equipment. While affordable and easy to install, they are not designed for ethanol-rich fuels or modern high-pressure setups.

-

Compatible with: Gasoline (non-ethanol), diesel

-

Best for: Lawn mowers, older carbureted cars, garden equipment

-

Compatible Fittings: Only compatible with inverted flare fittings.

Note: Avoid using NBR hoses with E10, E85, or ethanol blends—they’ll degrade quickly.

Need an economical solution? Browse our NBR fuel hose collection for reliable low-pressure options.

Tip: CPE Fuel Lines VS NBR Fuel Hoses

Marine Fuel Hoses

Corrosion-resistant, ideal for marine or salt-heavy environments

Marine fuel hoses are engineered for saltwater exposure, UV resistance, and low permeation. These hoses meet EPA or USCG standards, making them a safe, compliant choice for all types of marine fuel systems.

-

Designed for: Boats, jet skis, marine environments

-

Resistant to: UV rays, salt corrosion, fuel vapor leakage

Replacing fuel lines on your outboard engine? Choose from our certified marine fuel hoses for maximum safety and long-term durability.

Submersible Fuel Hoses

Designed for in-tank fuel pumps and full immersion

Submersible-rated fuel hoses are built to withstand full immersion in fuel, unlike standard hoses. They are essential for in-tank fuel pump setups, where the hose must resist both internal and external fuel exposure.

-

Used in: In-tank fuel pump setups, EFI conversions, fuel cells

-

Compatible with: E85, gasoline, diesel

Installing an EFI system? Only a submersible fuel hose is designed to resist internal swelling and external degradation inside the tank.

Aluminum Hard Lines & Transfer Hoses

Suitable for rigid mounting or fluid transfer in static systems

Aluminum fuel lines are ideal for clean, rigid installations where you want a fixed layout that won’t shift over time. Lightweight, corrosion-resistant, and easy to bend, aluminum is perfect for drag cars, street rods, and fuel transfer setups.

-

Best for: Long-run fuel routing, fuel system plumbing, static installs

-

Can be used with: AN fittings, compression tools, flare tools

Building a chassis-mounted fuel system? Choose from our aluminum fuel line kits. For flexible transfer needs, see our fuel transfer hoses.

Which Fuel Line Should You Choose?

Each fuel line type serves a different purpose. Picking the wrong one could lead to leaks, breakdowns, or safety issues. Here's a quick summary:

-

Need maximum heat resistance and ethanol compatibility? Choose PTFE fuel lines.

-

Want a cost-effective braided hose? Go with CPE fuel lines.

-

Working with older or low-pressure systems? Try NBR hoses.

-

Building for marine or high-humidity environments? Use marine fuel hoses.

-

Installing an in-tank fuel pump? Only submersible hoses are safe.

-

Looking for rigid, permanent fuel routing? Choose aluminum hard lines.

Not sure where to start? Browse our full fuel injection hose collection or contact our team for recommendations based on your specific setup.

Types of Fittings and How They Work

Choosing the right type of fitting is just as important as choosing the hose itself. Different hoses require specific types of fittings for proper sealing, performance, and durability.-

AN Fittings (Army-Navy Standard)

-

Size System: Expressed as AN followed by a number (e.g., AN6, AN8), where each size corresponds to a specific hose inner diameter.

-

Angles Available: 0°, 45°, 90°, 180°

-

Threads: UNF (Unified National Fine) thread pattern

-

Application: Used for fuel, oil, coolant, and other fluid systems

-

Example: AN6 for fuel lines, AN10/AN12 for oil cooler setups.

Type of AN Fittings

AN To AN Fittings: Connection fittings between AN standards, used for extending or adapting the same-size AN fittings.

AN To Barb Fittings: AN fitting to a hose barb fitting, used for connecting soft hoses.

AN To Barb Fittings: AN fitting to a hose barb fitting, used for connecting soft hoses. AN To INV Fittings: AN fitting to INV (Inverted Flare) fitting, commonly used in brake or fuel systems.

AN To INV Fittings: AN fitting to INV (Inverted Flare) fitting, commonly used in brake or fuel systems. AN To NPSM Fittings: AN fitting to NPSM (National Pipe Straight Mechanical) straight-thread fitting.

AN To NPSM Fittings: AN fitting to NPSM (National Pipe Straight Mechanical) straight-thread fitting. AN To UNF Fittings: AN fitting to UNF (Unified National Fine) threaded fitting.

AN To UNF Fittings: AN fitting to UNF (Unified National Fine) threaded fitting. AN To BSP Fittings: AN fitting to BSP (British Standard Pipe) threaded fitting.

AN To BSP Fittings: AN fitting to BSP (British Standard Pipe) threaded fitting. AN To AN With NPT Fittings: One end AN fitting, the other end with NPT thread.

AN To AN With NPT Fittings: One end AN fitting, the other end with NPT thread. AN Male To Female Tee Fittings: AN male-to-female tee fitting.

AN Male To Female Tee Fittings: AN male-to-female tee fitting. AN Male Tee Fittings: AN male tee fitting.

AN Male Tee Fittings: AN male tee fitting. AN Female To Male Tee Fittings: AN female-to-male tee fitting.

AN Female To Male Tee Fittings: AN female-to-male tee fitting. Fuel Banjo Fittings: Banjo fitting for fuel systems (hollow circular fitting often used with a bolt passing through).

Fuel Banjo Fittings: Banjo fitting for fuel systems (hollow circular fitting often used with a bolt passing through).

These fittings are specially designed to work with PTFE fuel lines, which have a very slick inner liner.

-

Key Feature: Include a brass or stainless steel ferrule (inner sleeve) that compresses the PTFE liner to create a tight seal.

-

Must be used with: PTFE hoses only

-

Installation: Requires careful assembly to prevent leakage

PTFE Fitting AN Thread Size Reference Table

PTFE (Teflon) hose fittings use specialized AN threads to ensure a secure, leak-free seal. The chart below shows the typical AN thread specifications used for PTFE hose ends, including external and internal thread diameters, hex sizes, insertion hose sizes, and operating conditions.

| AN Size | Thread Spec (UNF) | External Thread Ø | Internal Thread Ø | Hex Size A (mm) | Hex Size B (Insert Side) | Working Pressure | Operating Temp |

|---|---|---|---|---|---|---|---|

| AN3 | 3/8-24 UNF | Ø9.3 mm | Ø8.6 mm | 12.7 mm | 12.7 mm | 1500 PSI | -40°F ~ 230°F (-40°C ~ 110°C) |

| AN4 | 7/16-20 UNF | Ø11 mm | Ø9.9 mm | 14.4 mm | 16 mm | 1500 PSI | -40°F ~ 230°F (-40°C ~ 110°C) |

| AN6 | 9/16-18 UNF | Ø14.1 mm | Ø13 mm | 17.5 mm | 19.05 mm | 1500 PSI | -40°F ~ 230°F (-40°C ~ 110°C) |

| AN8 | 3/4-16 UNF | Ø18.9 mm | Ø17.6 mm | 22.2 mm | – | 1500 PSI | -40°F ~ 230°F (-40°C ~ 110°C) |

| AN10 | 7/8-14 UNF | Ø22.1 mm | Ø20.5 mm | 25.5 mm | 27 mm | 1500 PSI | -40°F ~ 230°F (-40°C ~ 110°C) |

| AN12 | 1-1/16-12 UNF | Ø26.8 mm | Ø25 mm | 30.2 mm | 31.85 mm | 1500 PSI | -40°F ~ 230°F (-40°C ~ 110°C) |

-

No clamps or collars needed

-

Quick install

-

Not ideal for high-pressure or PTFE lines

Barb-Style Fittings — Dimensional Specifications

Barb-style fuel hose fittings rely on mechanical grip—the barb (hooked ridges) is inserted directly into the hose to form a tight seal. The following chart outlines the dimensional data for various AN sizes:

| AN Size | Thread Spec (UNF) | A1 Ø (mm) | A2 Ø (mm) | A3 Ø (mm) | A4 Ø (mm) | A5 Ø (mm) | A6 (mm) | A7 Ø (mm) |

|---|---|---|---|---|---|---|---|---|

| AN4 | 7/16-20 UNF-2B | Ø6.7 -0.1 | Ø8.8 +0.05 | Ø8.6 ±0.05 | Ø15 | Ø16 -0.23 | 7.1 ±0.1 | (Ø9.9 +0.08) |

| AN6 | 9/16-18 UNF-2B | Ø9.4 +0.1 | Ø12 -0.07 | – | Ø20.2 | 18 +0.2 | 41.7 ±0.1 | (Ø12.94 +0.08) |

| AN8 | 3/4-16 UNF-2B | Ø12.5 +0.1 | Ø15.4 +0.05 | Ø15.1 ±0.05 | Ø20.8 | 21.5 +0.2 | 48.6 ±0.1 | (Ø17.55 +0.08) |

| AN10 | 7/8-14 UNF-2B | Ø15.5 -0.1 | Ø18.3 -0.05 | Ø17.9 ±0.05 | Ø25 | 24.5 +0.25 | 54.6 ±0.1 | (Ø20.5 +0.08) |

| AN12 | 1 1/16-12 UNF-2B | Ø18.5 +0.1 | Ø22 -0.05 | Ø21.6 ±0.05 | Ø30.8 | 27 +0.2 | 62.6 ±0.1 | (Ø25 +0.08) |

-

All dimensions are measured in millimeters (mm).

-

Tolerances are listed to ensure precision during CNC manufacturing and QC inspection.

-

A1–A7 refer to key interface points used for thread matching, hose insertion, and clamping clearance.

-

'UNF-2B' indicates Unified National Fine thread class 2B (internal thread).

Swivel fittings are two-piece fittings that allow the hose end to rotate independently from the fitting body.

-

Prevents: Hose twisting during installation

-

Best for: Tight or angled spaces

-

Common Use: With CPE braided hoses

Swivel Fitting Installation Overview

-

Cut the hose cleanly and remove any tape at the end.

-

Insert the hose into the socket using a twist-push motion until fully seated.

-

Apply a small amount of oil on the fitting to ease assembly.

-

Screw the fitting into the socket until there’s a 1mm gap between the fitting and the socket.

-

Check that the socket hasn’t moved.

AN Swivel Fittings Size Reference Chart

When selecting the correct AN swivel fitting, it's essential to understand the thread specifications, hex sizes, and compatible hose diameters. The table below shows common AN (Army-Navy) fitting sizes, along with thread specs, hex sizes, working pressure, and temperature range.| AN Size | Thread Size | External Thread Ø (mm) | Internal Thread Ø (mm) | Hex Size (mm) | Working Pressure | Operating Temp |

|---|---|---|---|---|---|---|

| AN4 | 7/16-20 UNF | Ø11 | Ø9.9 | 14.4 mm | 5000 PSI | -60°F ~ 400°F (-51°C ~ 204°C) |

| AN6 | 9/16-18 UNF | Ø14.1 | Ø13 | 17.5 mm | 5000 PSI | -60°F ~ 400°F (-51°C ~ 204°C) |

| AN8 | 3/4-16 UNF | Ø18.9 | Ø17.6 | 22.2 mm | 5000 PSI | -60°F ~ 400°F (-51°C ~ 204°C) |

| AN10 | 7/8-14 UNF | Ø22.1 | Ø20.5 | 25.5 mm | 5000 PSI | -60°F ~ 400°F (-51°C ~ 204°C) |

| AN12 | 1-1/16-12 UNF | Ø26.8 | Ø25 | 30.2 mm | 5000 PSI | -60°F ~ 400°F (-51°C ~ 204°C) |

-

Tool-Free Install/Removal

-

Best for: Modern fuel injection setups

-

Note: Must match the vehicle’s fuel rail or filter end design

-

Hardline, Barb, Weld-On, Cap & Plug Fittings

-

Barbed Fittings: Often used with rubber or NBR hoses (requires hose clamps)

-

Weld-On: Used in custom fuel tanks or aluminum lines

-

Caps & Plugs: Sealed unused ports

Types of Hose Fittings by Hose Type

| Hose Type | Recommended Fittings | Notes |

| CPE Hose | Swivel fittings, Push-in | Do not use with PTFE fittings or barbed ends |

| PTFE Hose | PTFE-specific flare fittings | Must use PTFE ferrule + flare nut |

| NBR Hose | Barbed fittings + clamps | Best with inverted-style clamps |

| Submersible | Barbed + hose clamp | Must handle full fuel immersion |

Understanding AN Fitting Sizes

| Term | Description |

| AN Size | Size indicator (e.g., AN6 = 6/16 inch = 3/8 inch) |

| Hose Size | Inner diameter the fitting fits |

| Thread Size | Unified fine thread (UNF), e.g., 3/8-24 |

| Pipe Thread (NPT) | Tapered thread for fuel/oil plumbing |

| M Threads | Metric threads, e.g., M18x1.5 |

-

Example: AN6 has a thread size of 9/16 inch -18 UNF.

-

3/8-24 SAE: 3/8 inch is the diameter, 24 threads per inch, SAE is the standard.

-

NPT: Tapered American pipe thread used for pressure sealing.

-

M18x1.2: Metric thread, 18mm outer diameter, 1.2mm pitch.

Installation Tips by Fitting Type

Swivel Fitting Installation Tips

-

Ensure clean hose ends with no tape.

-

Use aluminum-friendly tools (avoid scratching).

-

Use plastic vise jaws or protective tape.

-

Check socket position after installation.

PTFE Fitting Installation Tips

-

Always remove tape before assembly.

-

Use a small screwdriver to gently flare the braid.

-

PTFE inner sleeve must be positioned properly.

-

Inner sleeve is single-use only – do not reuse.

-

Tighten using correct wrenches and secure in vise with care.

Barbed/Inverted Fitting Tips

-

Do not use lubricants – may cause hose slippage.

-

Clamp placement should be centered on the barbed section.

-

Use worm clamps or EFI-rated hose clamps.

-

Protect the fitting during install using soft jaws or padding.

How to Match the Right Hose and Fitting

Choosing the correct hose and fitting combination is essential for ensuring leak-free operation, long-term reliability, and safety in any fuel, oil, or fluid system. The right match depends on pressure ratings, fluid compatibility, temperature exposure, thread types, and installation method.Choosing Based on Pressure and Temperature Requirements

Different hose materials and fittings are rated for specific operating conditions. Always choose a hose/fitting combo that exceeds the system’s maximum pressure and temperature.| Hose Type | Max Temp | Max Pressure | Ideal For |

| PTFE | ~500°F / 260°C | 2500+ psi | E85, ethanol, high-temp, high-pressure |

| CPE | ~300°F / 150°C | ~350–1000 psi | General performance fuel systems |

| NBR/Rubber | ~212°F / 100°C | ~150–250 psi | Low-pressure carb systems, garden engines |

| Marine | ~200°F | Varies | Saltwater, UV-exposed environments |

Matching Hose Diameter with Thread Size

Understanding AN sizes and matching them to the proper fitting threads is crucial. AN sizing is based on the inner diameter of the hose in 1/16-inch increments.| AN Size | Hose I.D. | Typical Use |

| AN4 | 1/4 inch | Fuel return lines, vacuum |

| AN6 | 3/8 inch | Main fuel lines (EFI, carb) |

| AN8 | 1/2 inch | Oil coolers, high-flow fuel |

| AN10/12 | 5/8 inch+ | Oil lines, breather systems |

-

AN fittings use UNF (Unified National Fine) threads

-

PTFE fittings typically require flare-style threads

-

Barbed fittings use hose clamp retention (no thread sealant)

Pre-Made Fuel Line Kits vs. Custom Assemblies

-

Convenient, matched components

-

Ideal for first-time installs or common applications (LS swaps, fuel filter lines)

-

Usually includes fittings + hoses cut to length

-

Allows precise routing and fit

-

Useful for complex builds or tight engine bays

-

Choose specific hose type, fitting angles (0°, 45°, 90°), and thread types

Installation Tips and Best Practices

-

Never use Teflon tape on AN or flare fittings

-

Use PTFE paste or thread sealant for NPT threads only

-

Ensure PTFE ferrules are seated correctly during assembly

-

Use aluminum AN wrenches to prevent scarring fittings

-

Use soft-jaw vise blocks to protect fittings during tightening

-

Rotary cutters or shears for clean hose cuts

-

Mark hose/fitting alignment before tightening to detect twist

-

Check socket or nut movement post-install

-

Allow ~1mm gap between nut and fitting body (swivel types)

FAQs

PTFE vs. CPE — What's the Difference?

-

PTFE (Polytetrafluoroethylene) hoses feature a hard, non-stick inner liner that offers superior chemical resistance, higher temperature tolerance, and compatibility with aggressive fuels including E85, methanol, and brake fluids. They are ideal for high-performance or racing applications.

-

CPE (Chlorinated Polyethylene) hoses have a rubber-like inner layer. They offer good flexibility and are compatible with most oils, fuels, and coolants, but not recommended for use with E85, as it may reduce lifespan.

Are Push Lock Fittings Reliable?

-

Yes, Push Lock fittings are reliable for low- to medium-pressure systems (typically under 250 PSI).

-

They don’t require hose clamps, making them quick to install. However, they’re not recommended for high-pressure fuel injection systems or under-hood areas with extreme heat.

When Should I Use Quick Disconnects?

-

Quick Disconnect (QD) fittings are ideal for EFI (Electronic Fuel Injection) systems, or any setup where you need to frequently remove or service lines.

-

They allow tool-free connection/disconnection, reduce service time, and improve safety by minimizing fuel spillage.

Can You Mix Hose Types in the Same System?

-

Technically, you can mix hose types (e.g., PTFE, CPE, rubber), but you must:

-

Match each hose with the correct fitting type

-

Ensure chemical compatibility (e.g., don’t use CPE for E85)

-

Check temperature and pressure ratings are consistent across the system

-

Recommended Products & Further Reading

Fuel Lines Collection

Explore a wide range of fuel hoses suited for various applications—PTFE, CPE, rubber, marine, and more.Browse the full collection: 👉 Fuel Line Kits & HosesFittings Collection

Find the right fitting for your system: AN fittings, push lock, PTFE-specific, quick disconnects, and more.Browse the fittings collection: 👉 Hose Fittings & AdaptersExplore More with EVIL ENERGY

Subscribe to Our Newsletter

Join the EVIL ENERGY community and stay informed:- Dive into discussions about performance upgrades, tuning insights, and product knowledge

- Get early access to exclusive offers, limited-time promotions, and new product launches

Follow Us on Social Media

EVIL ENERGY is about so much more than meets the eye. Step into a dynamic world of motorsports, builds, and behind-the-scenes action:- Catch event highlights, real-world installs, and product releases

- Discover creative builds, community tips, and the culture that drives our passion

Follow EVIL ENERGY here

![EVIL ENERGY 4/6/8/10AN PTFE Fuel Line Kit | E85 Nylon Braided Hose | 16/20FT Black Black with Comprehensive Fittings [20FT]](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598065_165x.png?v=1742144807)

![ptfe hose fitting kit [16FT]](http://www.ievilenergy.com/cdn/shop/files/Test-2025-Evilenergy-125598171_165x.png?v=1742144807)

![CPE Fuel Line[25FT]](http://www.ievilenergy.com/cdn/shop/files/25FTCPE_FuelLine_165x.png?v=1735220649)

![CPE Fuel Line[20FT]](http://www.ievilenergy.com/cdn/shop/files/20FTCPE_FuelLine_165x.png?v=1735220649)